Home » Capabilities

Capabilities

Our goal is to deliver directly to your production line the high-quality, repeatable filtration or separation solution you need, at the lowest cost of supply. We achieve this by using our global supply chain and expertise, our extensive manufacturing, and production facilities, the experience of our Design Engineers, and our skill in supply chain management.

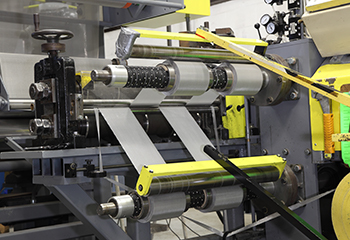

Processing Capabilities

Extensive manufacturing capabilities to deliver your mesh precisely as you specify.

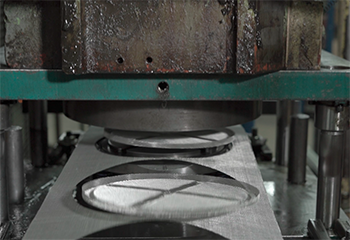

Forming & Stamping

An in-house tool and die shop enable us to produce exactly the filtration components you need.

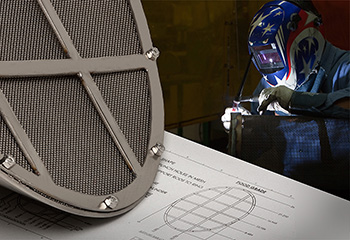

Engineered Solutions

Our Engineers collaborate with your design team on challenging filtration and separation requirements.

Materials Management

We manage your production line – a certified, quality product delivered exactly when you need it.