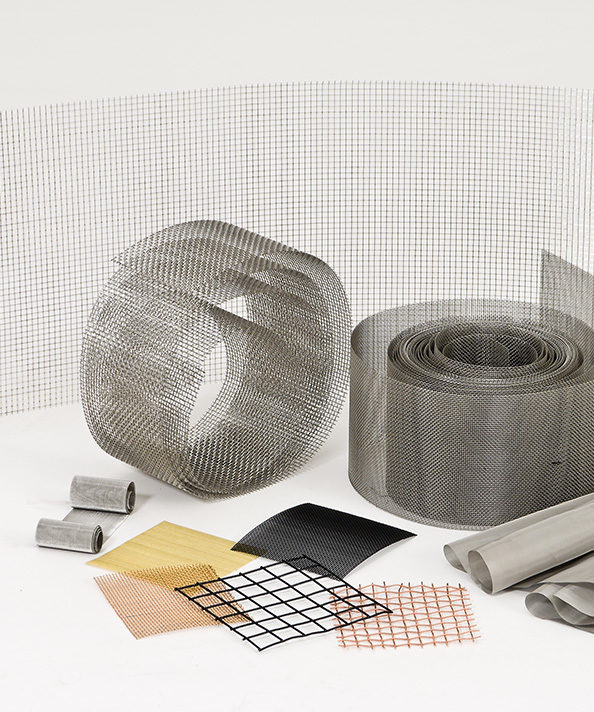

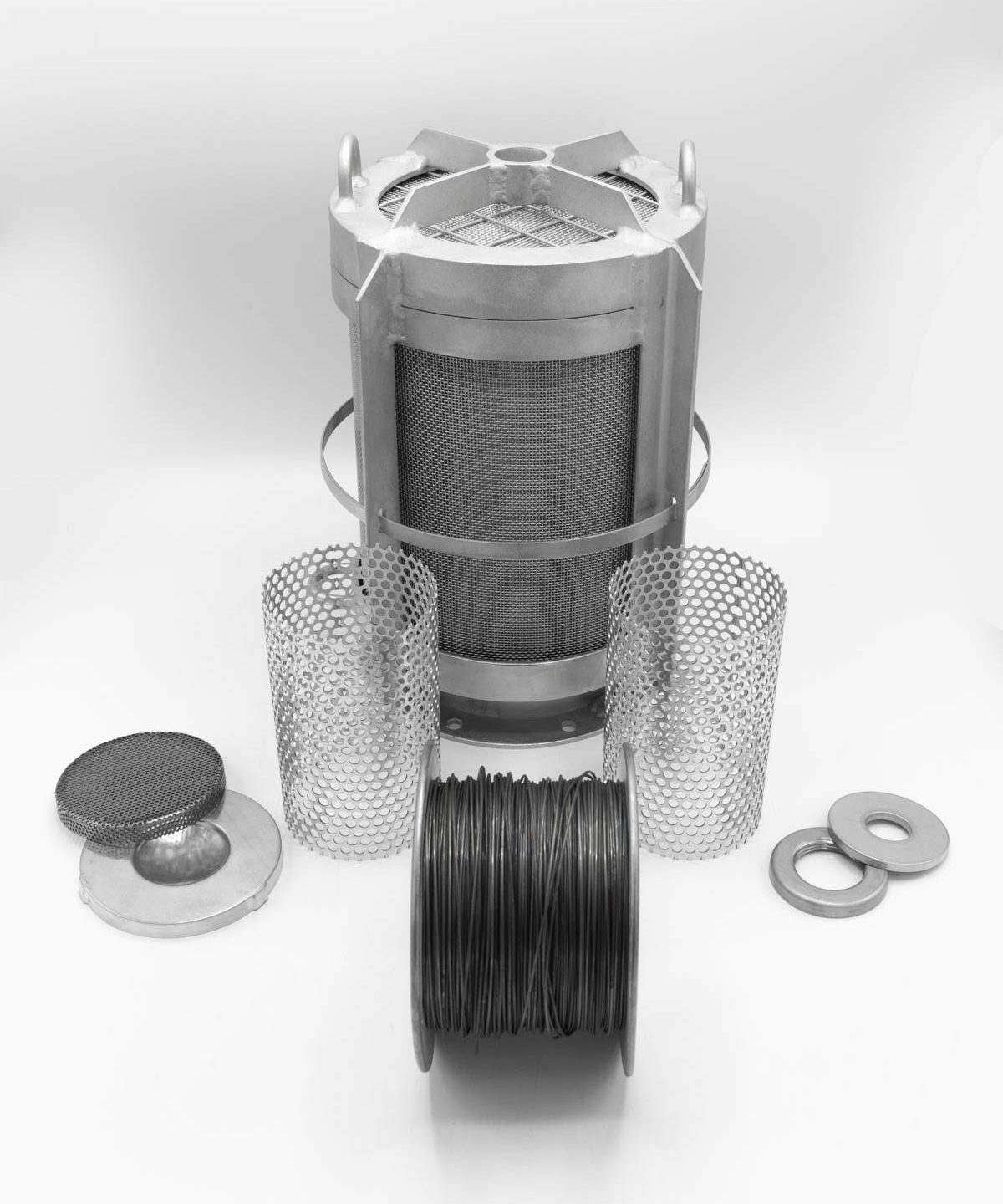

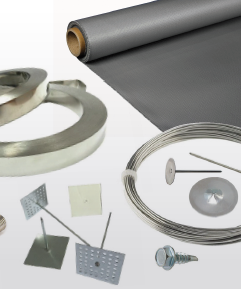

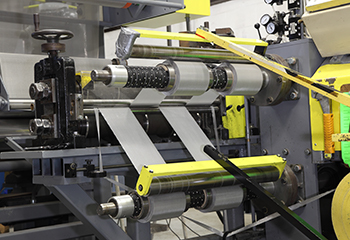

Our Product Lines

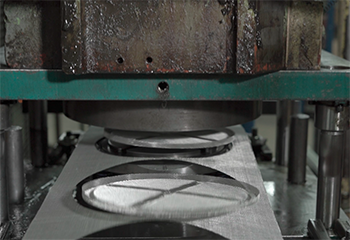

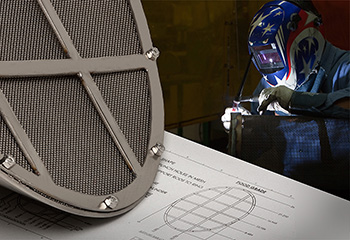

Engineered Filtration Solutions

Using our deep expertise, we collaborate with your engineers to develop and manufacture the solution you need.

Testimonials

Worldwide Locations

Gerard Daniel provides its customers with the highest level of services and support across the globe.

Worldwide Headquarters & U.S. Manufacturing Location

150 Factory Street, Hanover PA, 17331, United States

Manufacturing & Distribution Locations

Canadian Headquarters & Manufacturing Location

205 Courtney Park Drive West, Suite 101, Mississauga, ON, L5W 0A5, Canada

European Headquarters & Manufacturing Location

Mountmahon Industrial Estate Abbeyfeale, County Limerick, V94 KW59, Ireland

Manufacturing Location

13055 Jurupa Avenue

Fontana, CA 92337

United States

Worldwide Headquarters & Manufacturing Location

150 Factory Street

Hanover, PA 17331

United States

Manufacturing Location

100 Wildwood Street

Adamsville, TN 38310

United States

Canadian Headquarters & Manufacturing Location

205 Courtneypark Drive West | Suite 101

Mississauga, Ontario, L5W 0A5

Canada

European Headquarters & Manufacturing Location

Mountmahon Industrial Estate

Abbeyfeale, Co. Limerick, V94 KW59

Ireland

Manufacturing & Distribution Location

110 Iron Mountain Rd.

Mine Hill, NJ 07803

Manufacturing & Distribution Location

8527 Monroe Rd.,

Houston, TX 77061

Manufacturing & Distribution Location

7136 South Yale Suite 300,

Tulsa, OK 74136

Manufacturing & Distribution Location

7158 123rd Circle N.,

Largo, FL 33773