Micron Mesh Filters – Part Two: Balancing the Durability and Aperture of Filter Mesh

For this series on understanding wire mesh for filtration, in part one we discussed different mesh weaves and their roles in filter design. Here in part two, we will consider factors that degrade mesh performance as it relates to mesh aperture.

When choosing a micronic mesh for a filter application, key variables often overlooked are the durability of the mesh, the flow rate through that mesh – and how the two are connected. Micron mesh filters tend to suffer damage in four different ways: sustained high pressure, repeated pressure fluctuations, corrosion, and operator error when cleaning and servicing the filter.

For each of these sources of damage we will consider filter design missteps and review design best-practices to avoid them.

Sustained Pressure

As particles caught by the micron mesh filter gradually block the screen the back pressure will increase. In some instances, the operation of the system calls for periodic deblinding before the pressure exceeds a threshold beyond which the mesh suffers damage. Left unattended, this pressure could simply exceed burst pressure, which is a durability catastrophe. Before burst pressure is reached, however, less noticeable system failure can occur like exceeding a bypass valve setting, which could allow unfiltered fluid and solids where they are not wanted. An improved design can raise the damage threshold of the filter, and better maintenance adherence can prevent the mesh from suffering damaging pressures to begin with.

Repeated Pressure Cycling

In a properly designed and maintained filter system, the durability of the micron mesh should not be significantly compromised by normal use and operation. In addition to considering the effects of constant pressure on a mesh filter, the frequency of pressure changes must be considered as well. A mesh that might be just fine against a constant pressure of 100 psi could fail quickly from pressure oscillating between 0 and 50 psi.

Pressure oscillations like you get from a diaphragm pump or an automated system repeatedly triggering a backflow cleaning cycle can compromise the mesh by work-hardening the wire far sooner and with less overall pressure differential than a system with a steady pressure.

Overhandling

Over the course of a filtration session the micron mesh is slowly blocked by particles. This will reduce the volumetric flow rate through the filter or result in a differential pressure building until the same volumetric flow rate is achieved through brute force. The added pressure can cause wear and damage to the mesh. Alternatively, the filter will need more frequent cleaning and maintenance, increasing the opportunities for wear and tear to the mesh through handling (or mishandling). The loss of production time can also have a significant economic impact.

Corrosion and Abrasion

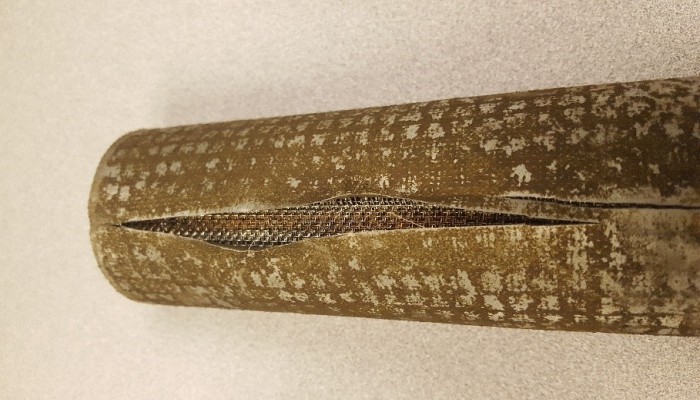

Micron mesh filters can also fail from corrosion and abrasion. While these durability issues may not seem tied directly to aperture, they are not entirely independent of it either. As the wires are polished down by micro-abrasives or eaten away by corrosives, not only are the thinner wires more likely to tear, but the apertures will also widen and let bigger particles through. Your filtration mesh expert can advise you on wire mesh alloys to stand up to even the most extreme corrosive or abrasive fluid.

Start with Durability in Mind

- Don’t make your filter work harder than it must. Choose a micron mesh with a particle retention no smaller than necessary.

- Instead of selecting a micron filter mesh with the greatest possible flow rating, consider one with the same micron retention size but with a more robust construction, even if it means increased overall surface area of mesh will be needed. It will last longer and require less maintenance.

- Establish maintenance protocols that minimize chances of damaging the mesh filter or construct the filter to stand up to some rough handling.

- Reduce the possibility that the wires in the mesh can shift around relative to one another. This is called fixing the aperture of the mesh, which reduces the likelihood that manufacturing methods, pressure spikes, or operator mishandling will deform the mesh or distort its aperture. Ways to fix the aperture include:

- Calendaring, which compresses the mesh between two heavy rolling pins to flatten the knuckles and nest the warp and shute wires together at each wire intersection, so they are less likely to shift around during forming,

- Heat treating before forming. This reanneals the mesh and decreases the spring tension which makes forming more challenging. Heat treating after forming decreases stresses in the wires induced by forming.

- Sintering, which begins with calendaring to flatten the knuckles, then heat treating just below melting temperature to bond several layers of mesh together.

Consult a wire mesh filtration expert to learn more about striking the right balance between durability, aperture, and flow rate.

Gerard Daniel Expertise

At Gerard Daniel, we’ve been sourcing, weaving, and distributing wire mesh for 70 years and stock the largest range of inventory in North America. Our application engineers use their deep expertise in woven mesh and components to develop the most effective solution, collaborating with your design, development, and production teams to ensure the lowest cost to manufacture. Please reach out if you would like to learn more about our capabilities.