Fiber Molded Products: Shortening the Time to Market for New Products

Bringing any product to market is a lengthy and expensive process. In this article we will consider best practices for tooling prototyping and product development, giving special emphasis on prototyping deep-drawn products such as wire forms. Wire forms, here, refers to wire mesh, perforated, and expanded metals, all of which are Media Types used to produce wire forms. Following the correct process ensures the most cost-effective and expedient way for a manufacturer to get wire form prototypes created and to a customer for testing and approval.

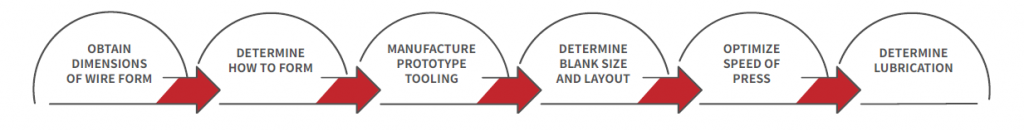

The Prototyping Process

Obtain Dimensions of Wire Form

Dimensions and specifications of the wire form must be determined prior to tooling development. This is typically in consultation with the fiber mold (also called pulp mold) manufacturer. Based on the industry and application of the product, an experienced deep drawing engineer will be able to recommend which media will help to create the best wire form for the job, while minimizing scrap and maximizing the longevity of wire form. Learn more about best practices for selecting the correct porous media type for your project here.

Determine How to Form

During this stage, it is most helpful to ask yourself the important questions: How deep is the wire form? Does the part involve an intricate design with lots of bends and crevices? Should it be manufactured using single or multiple stages, using a compound or progressive die set? Are there any trimming or auxiliary operations required? Your answers to these important questions allow you to better optimize the next steps in the prototyping process of wire forming.

Manufacture Prototype Tooling

Prototype tooling is used to determine how to produce correct sample wire forms for the pulp molder’s requirements, along with determining the final dimensions of the production tooling. Prototype tooling can be made from a softer material that can be easily machined and modified, yet stiff enough to produce prototype wire forms. The prototype tooling does not have a long lifespan, since the edges of the die will wear down quickly and the material being formed will wear into the tooling. Materials used most often are:

Benjamin Henneberger

Plastics and aluminum

These materials have a lower initial cost and are easy to make minor adjustments to in the prototyping process. With these materials, however, the tool does not have a long lifespan since the edges of the die will wear down quickly.

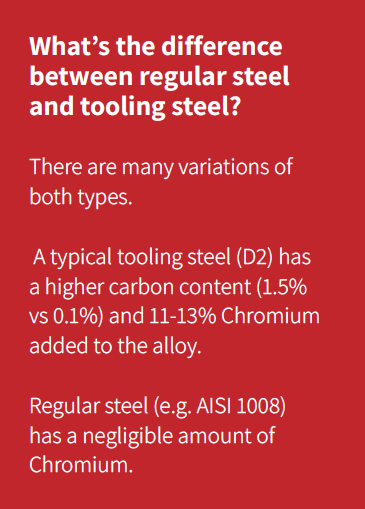

Tool Steel

This is more expensive to use in the prototyping stage, however, many times the soft tooling produced uses tool steel which can then be heat-treated after prototyping is complete to harden it for use in production. This selection has the potential to reduce costs in the long run.

Determine Blank Size and Layout

The deep drawing engineer will determine the required blank size and orientation of the wire form utilizing raw material sizes that minimize scrap. The efficient use of raw material drives costs out of the process.

Optimize Speed of Press

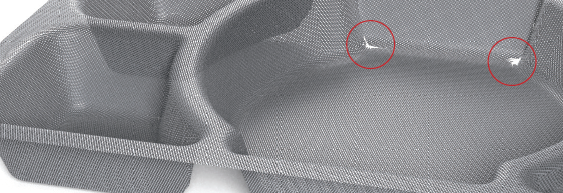

The speed of the press operation must be balanced against the production of repeatable high-quality wire forms. If the press goes too fast, rips or wrinkles may occur. Part of the prototyping process is determining the optimum speed at which the press can operate without producing scrap parts.

Determine Lubercation

The amount and type of lubricant that goes hand-in-hand with the speed of the press and are both keys to the final product. If too much is used, the material could flow excessively causing overlaps or tears. If there is not enough lubrication used, the material will not flow enough and this could cause tears and cracks.

Prototype Review

Once the prototype wire forms are submitted, the fiber mold manufacturer will review them by doing the following:

□ Visual and tactile check of the wire form

□ Quality check to the drawing

□ Ensure it is compatible with their pulp molding machinery and fits correctly

□ Verify it will consistently produce the pulp molded container to their customer’s specification

Remember, the prototyping of deep drawn wire forms is a trial-and-error process where skill and experience are key. It involves a lot of communication between the toolmaker, wire form producer, and pulp mold manufacturer.

Creating Production Tooling

Once the wire forms are signed off and approved, production tooling is manufactured. Skilled tool-makers will take the prototype tooling and use the final dimensions to machine the final production tooling from specialized tool steel. The tooling is then hardened by heat treating and is ready for production.

For fiber mold manufacturers overseeing the whole fiber molding process, prototyping new products, managing tooling, and producing wire forms can be challenging. Without the correct expertise, prototyping can be a lengthy process until repeatable good-quality wire forms are produced. One way of mitigating this is to work with a specialist in forming these media. This can help pulp mold manufacturers reduce the time to market, re-allocate manpower, and ultimately focus on the production of pulp molds for their customers.

Gerard Daniel Worldwide is a leader in wire cloth, associated wire mesh components, and deep-drawn products. Our proven prototyping and production tooling process, along with skilled toolmakers and a just-in-time customer delivery program, can benefit pulp molding customers by shortening the prototyping process and delivering production wire form molds sooner. If manufacturers have current tooling that is not performing, they can also repair, modify, maintain, and store the dies. For more information on pulp molding, click here.