Home » Capabilities » Forming & Stamping

Forming & Stamping

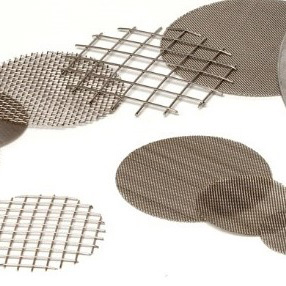

Drawn (Wire) Forms

We form both wire mesh/cloth and sheet metal – our engineers have experience with both. Forming wire mesh is an art as well as a science. It does not shape uniformly like sheet metal, because of the structure and open area of the mesh, and takes many years of experience to gain the know-how of how wire mesh behaves when formed. An experienced wire mesh toolmaker will know the best way to construct the die for the press in order to ensure a consistent flow with a repeatable form shaped every time. The toolmaker and production engineer work together and determine which type of press to use and whether to construct a single, progressive or compound die to form the component, depending on the shape, tolerances, and quantities to be formed.

Stamping

We have a wide variety of capabilities to stamp or punch many different types of components and production requirements – ranging from small, batched runs to high-volume production on our high-speed, multi-station presses.

We can punch all types of wire mesh – from low mesh counts of 2# and 4# through to mesh counts of more than 500#. Our expertise is holding extremely tight tolerances – up to one-tenth of a human hair is possible.

For production volumes that don’t justify investing the capital in a die for stamping, we can economically run small batches of ‘stamped’ parts using our laser cutter. We can also punch other sheet metal parts of filtration assemblies such as flanges, end caps, and bindings.

Edging

The edges of the wire mesh/cloth sometimes need to be treated to prevent them from loosening (fraying) or to help with the mesh rigidity. The edging can also be used to attach the mesh to its final use. Types of edging processes we can do are

- Hemming – where the mesh is folded back on itself and pressure is applied to the fold to hold. This is used with large mesh count cloth or mesh

- Welded – The intersections of the warp and chute wires are welded together to seal the edge

- U-Channel – Fits over the end of the wire mesh.

- White Canvas – Used for sealing the ends of vibrating separator screens.

Pleating & Cylindrical Production

Pleating – We can pleat wire mesh to different sizes (pleating is a type of fold formed through doubling the mesh back upon itself and securing it in place). This process allows for greater surface area and volume in a smaller area.

Cylindrical production – we manufacture many different types of cylinders most often used as a support media for a filtration assembly. Perforated cylinders, mesh cylinders, or custom sheet metal blanked cylinders, our production engineers determine the most efficient method of production.

Assembling Filtration & Separation Components

We assemble many different components (flanges, end caps, cylinders, support media) to the mesh and produce a finished filtration or separation assembly using many of the capabilities you see listed on this website.

Quick Prototyping

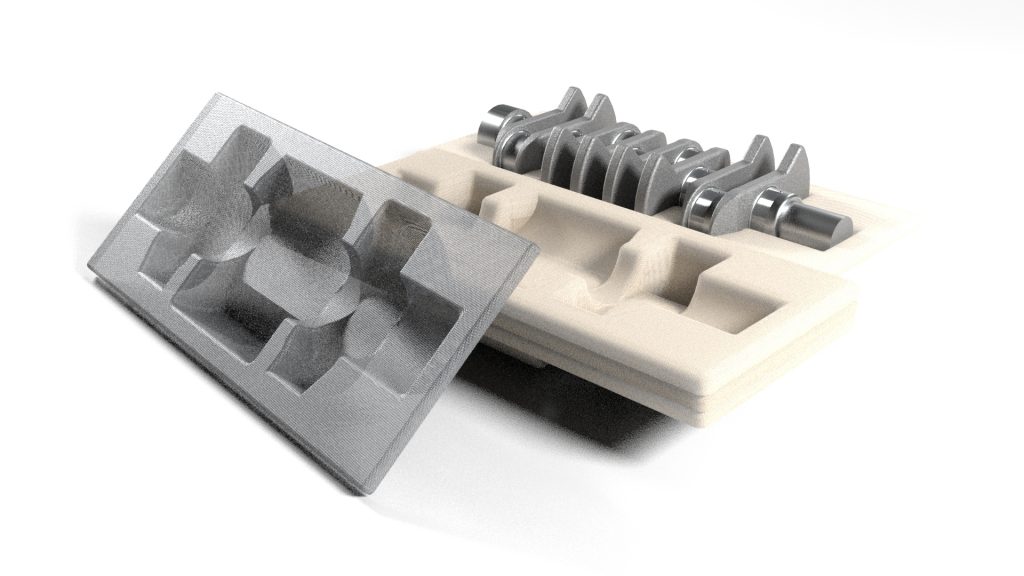

We know that quick prototyping is essential for our customers to finalize their projects in a timely manner. Whether you already have a print or developed it in collaboration with our Engineers, we use our origins in small-batch productions, our in-house tool and die department, skilled engineers, and small-batch run machines (including 3D printers, laser cutters, and other equipment) to expediently create a high-quality prototype for you to use in your development process. Once we have sign-off on a prototype, we have extensive experience in producing the first article submission in many industries, including automotive and aerospace.

Complete Tool & Die Shop

Our complete tool and die shop offers many unique advantages over many other manufacturers. Not only are we able to react quickly with prototyping and first article submissions, but for production, we are also able to rapidly service, re-build, repair, and in some cases make minute tweaks to tooling that in other cases may not be done if it involved sending tooling out for repair.

Our skilled tool and die makers have an average service length of 20 years, and work with a variety of machines, from EDMs, CNCs, to time-tested manual lathes – each used to deliver the exact specification for the job in hand.