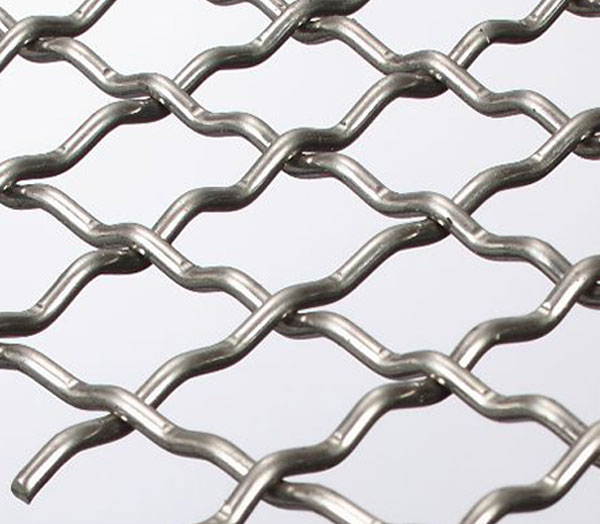

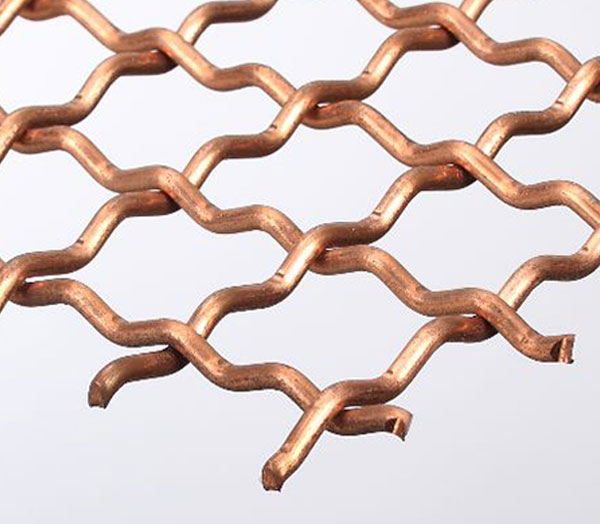

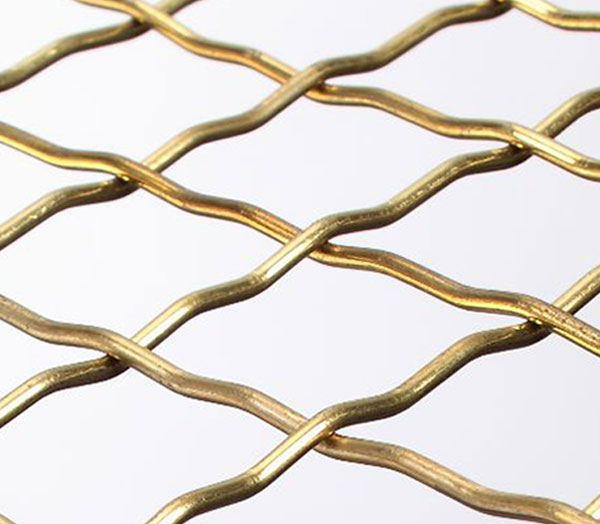

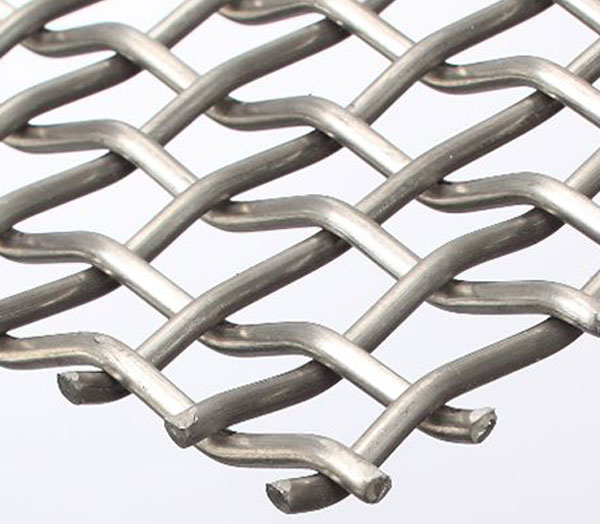

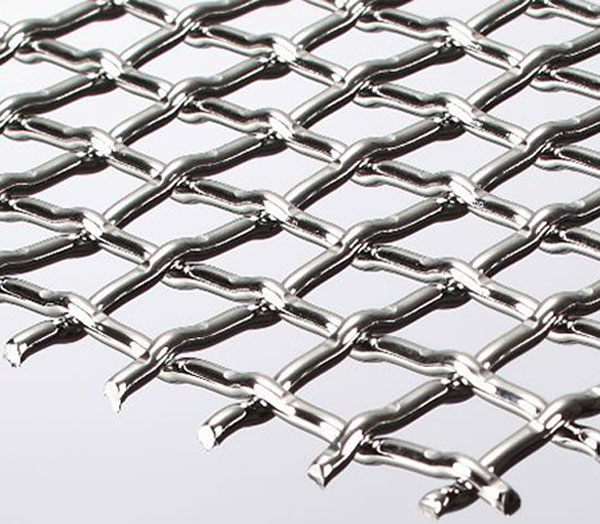

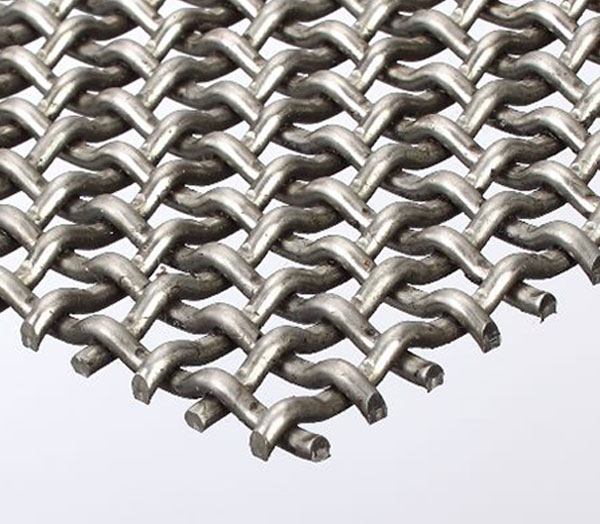

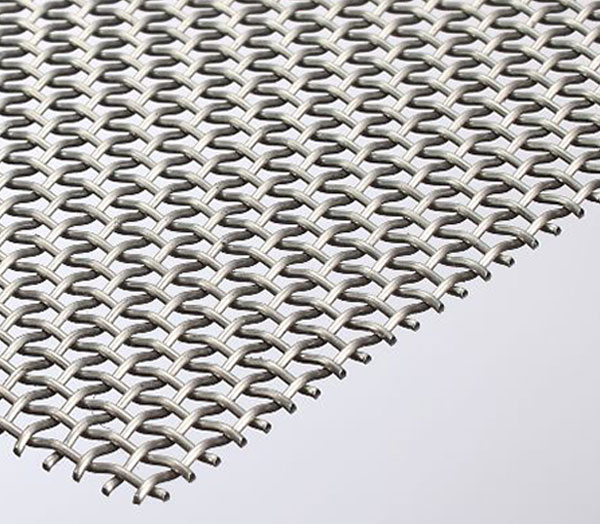

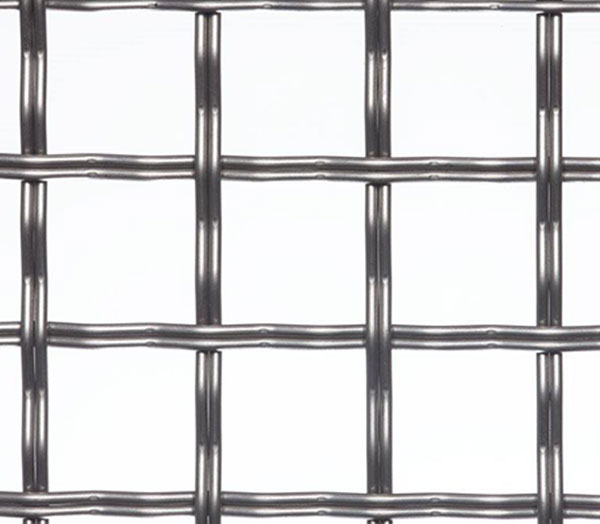

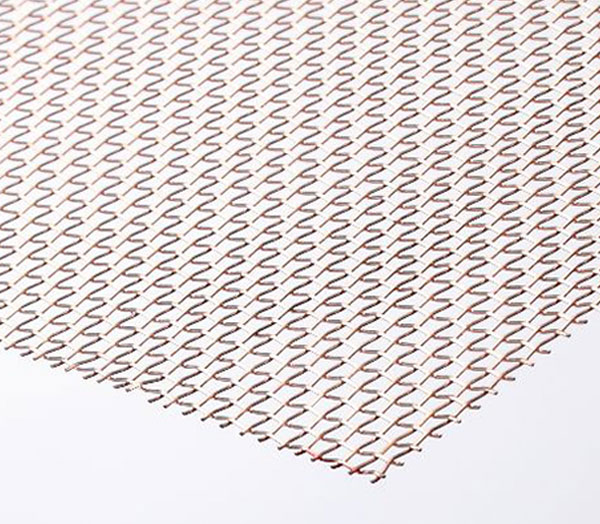

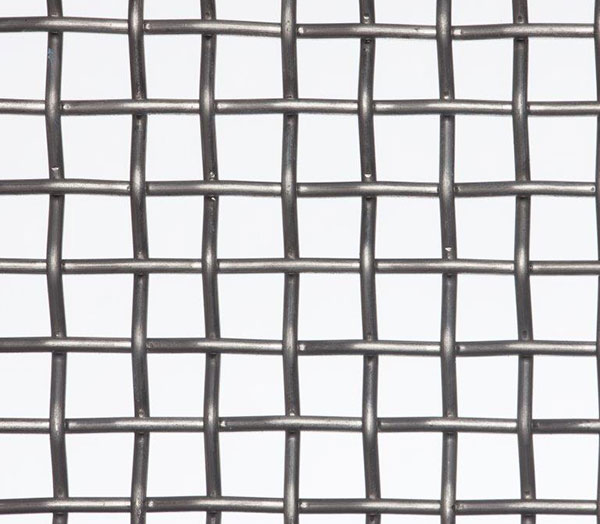

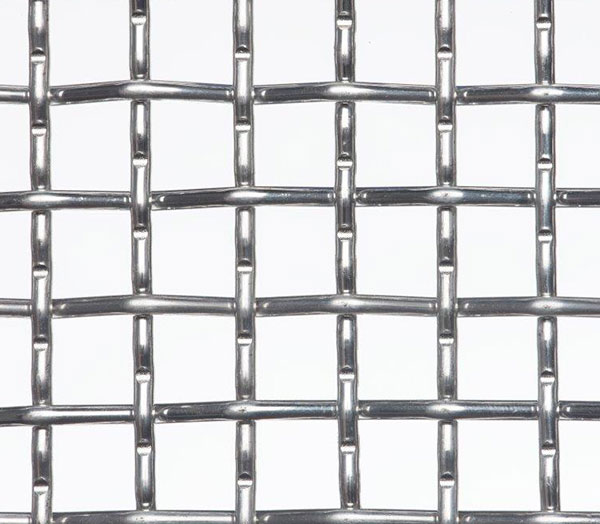

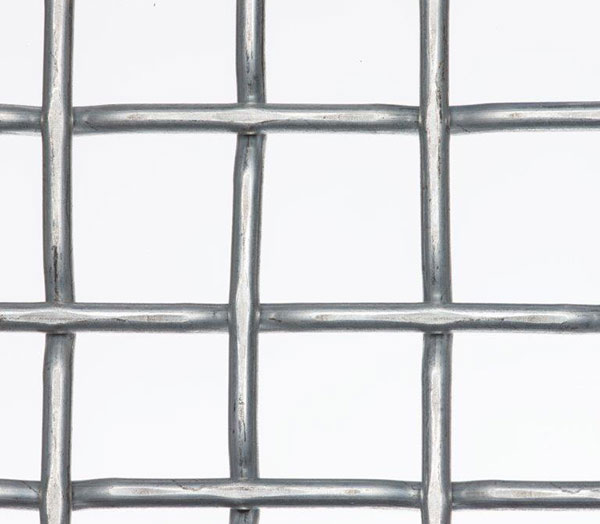

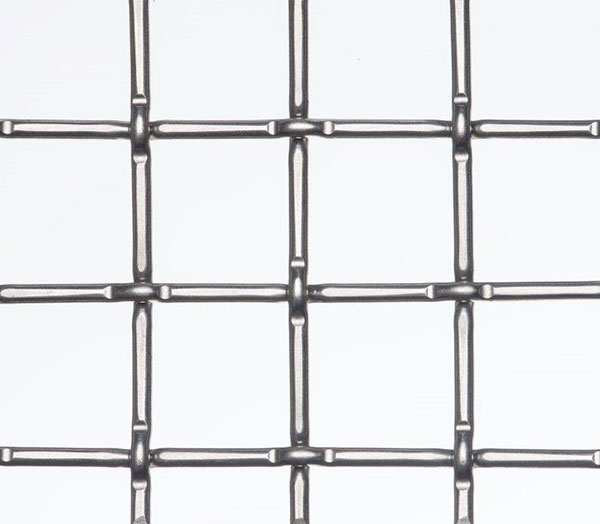

Crimped Wire Mesh

Pre-crimping wire enables the mesh to lock together, creating a tight weave with good rigidity and pleasing aesthetics. It is used extensively in architectural applications, as infill panels, cages and decoration. It is also used in acoustics, filtration, bridge guards, aerospace parts, rodent control, and truck grills.

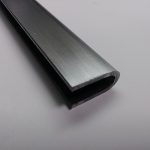

Used to frame welded wire mesh like a picture, U Channels have 3 main functions;

- Encloses the mesh taking away any sharp edges (depending on how the edges are cut)

- Allows it to be welded or attached mechanically into guard rails

- Stiffens the mesh and prevent damage to the wires.

We stock 12- and 18-gauge plain steel U Channels with a 1” width, supplied in 10ft lengths. Other gauges and Stainless or Aluminum are also available.

DETAILS

Mesh Count:

1# - 4#, other sizes available

Porosity:

56% - 94.1%