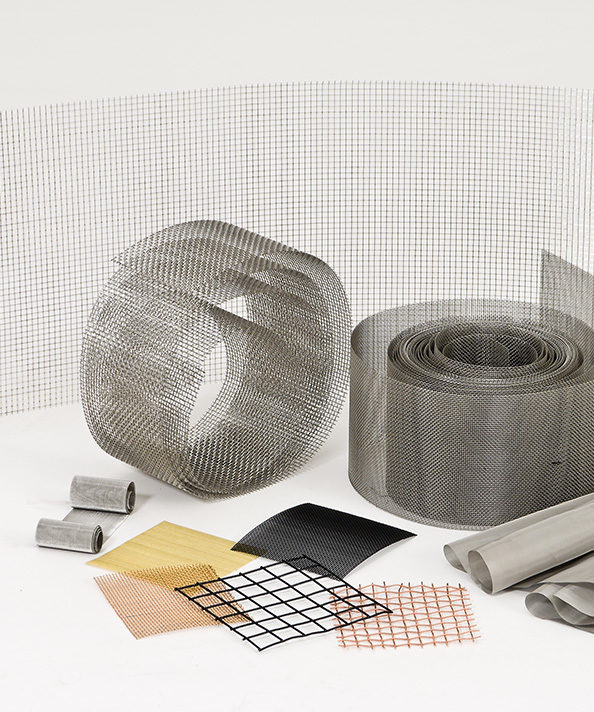

Tapes & Facings

Gerard Daniel carries multiple tape options for all your insulation and construction needs. Each option comes from a different material for the purpose of fitting a different task, allowing for a wide variety of uses to be covered under the options offered. These options include FSK, PVC, ASJ, and aluminum foil tape.

Gerard Daniel’s specially formulated Film Scrim Kraft (FSK) Tape is a 3-way Foil Scrim Kraft backing tape combined with a high performance solvent acrylic adhesive. Our FSK tape offers excellent heat conduction and reflection, as well as reliable and durable bonds in both high and low temperatures.

Gerard Daniel’s PVC Tape is a high-quality PVC film in combination with an again stable solvent rubber adhesive. Our PVC Tape has a high adhesive force, and is both flexible and supple.

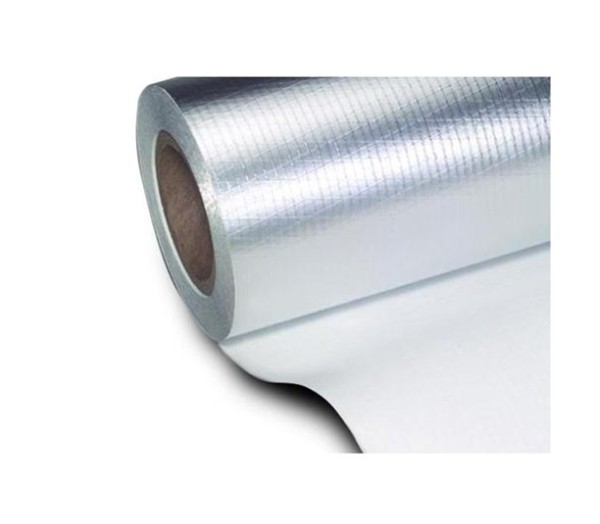

Gerard Daniel’s specially formulated All Service Jacket (ASJ) tape is a backing tape combined with a high-performance cold-weather solvent acrylic adhesive. ASJ is an excellent vapor barrier and offers a low moisture vapor transmission rate.

Gerard Daniel’s Aluminum Foil Tape is a high tensile strength aluminum foil backing tape with an epoxy resin coated on its surface. It shows fantastic heat conduction and high performance solvent acrylic adhesive, protected by an easy release silicone paper.

This non-adhesive ASJ facing tape is mainly used as a facing and vapor barrier for glass wool, rock wool, and mineral wool insulation or steel structure installation. It is also suitable for other insulation applications where a general use vapor retarder is needed due to it emissivity.