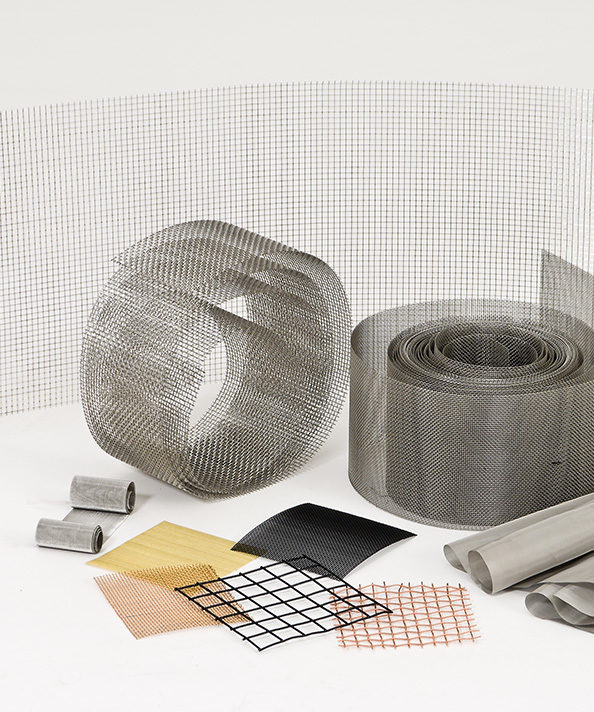

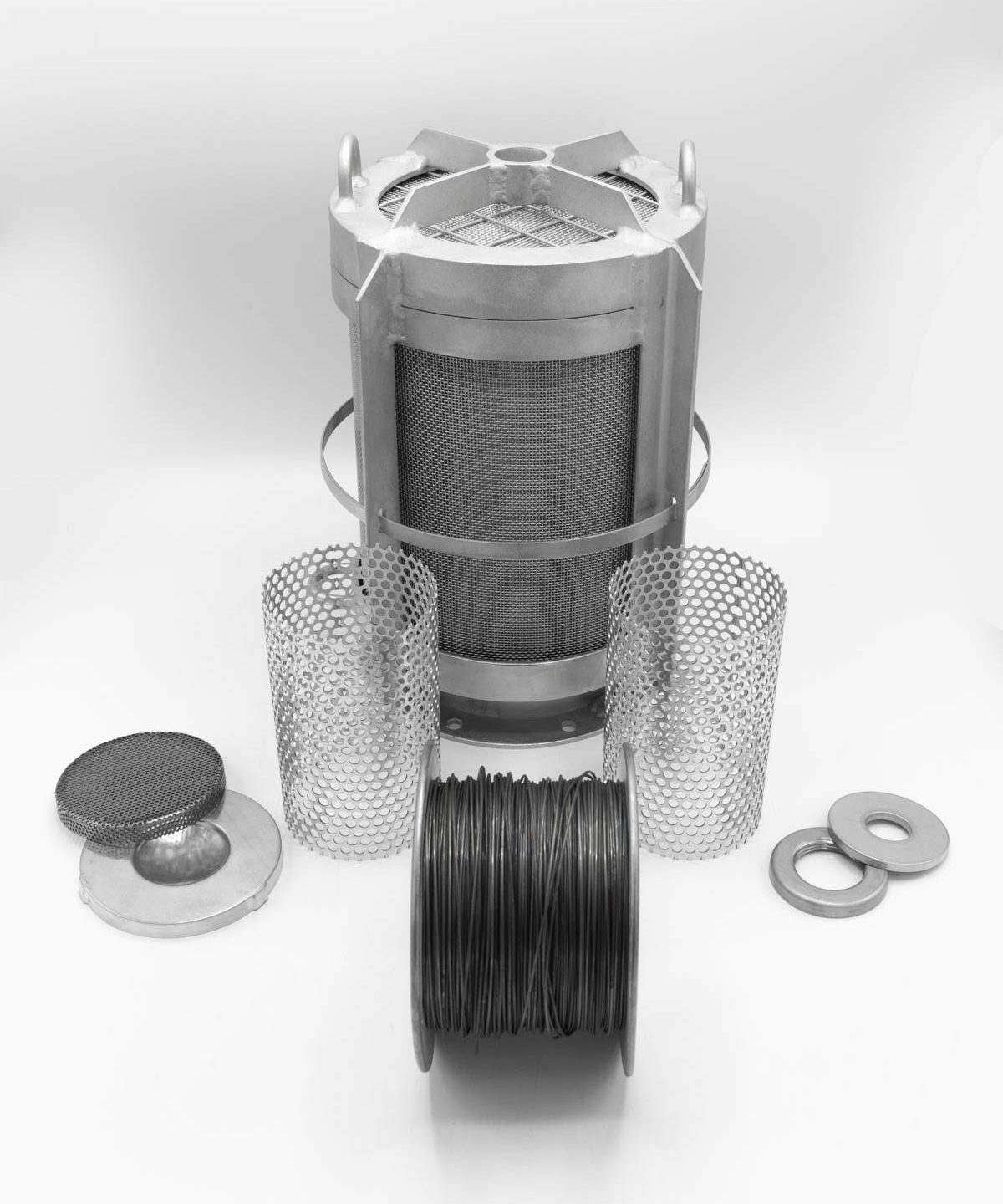

Strainer Assemblies

Strainers come in many sizes – from small fluid strainers to large dewatering pulp separators. Their main function is universal – the ‘first pass’ of filtration before finer filtration takes place (if necessary). Strainers typically use square or plain mesh as the filter media. As a strainer manufacturer, Gerard Daniel’s expertise with mesh makes us a leading expert. Our engineers can work with you to develop a custom strainer solution for your application.

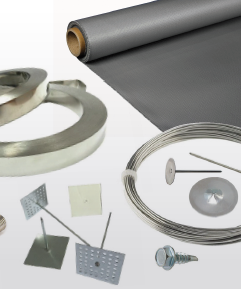

Air vent solutions can be stand-alone large mesh solutions or combined inside a plastic housing. While mainly used in vehicles, we provide both types and can work with you to develop the best solution for your design.

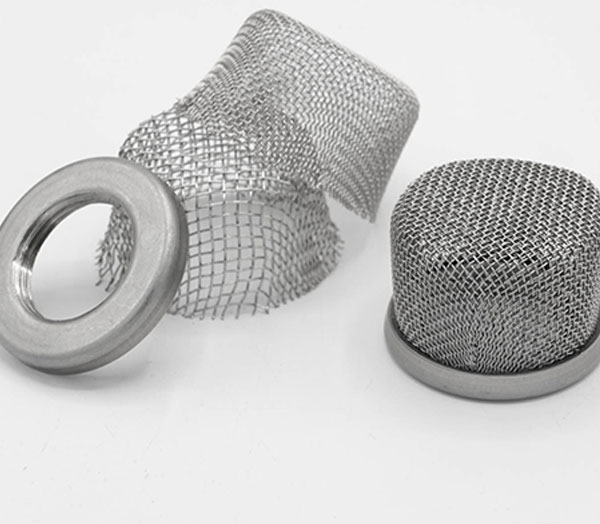

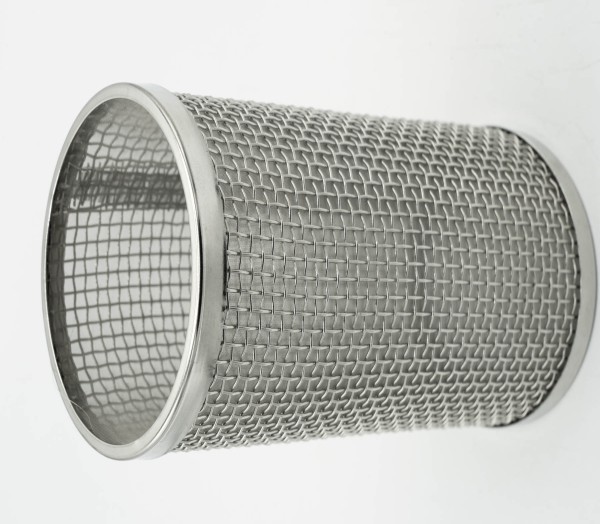

Fluid strainers may also be referred to as industrial basket strainers or valve strainers. Similar to the inline filters in the filter section, they are used as ‘catchers’ in oil and fuel lines to prevent larger particles from reaching the moving parts of the engine.

Large dewatering screens are designed to separate large volumes of liquid and heavy products such as food waste or other large particulates floating in liquid. They are mounted on stand-alone equipment and often made using wedge wire.

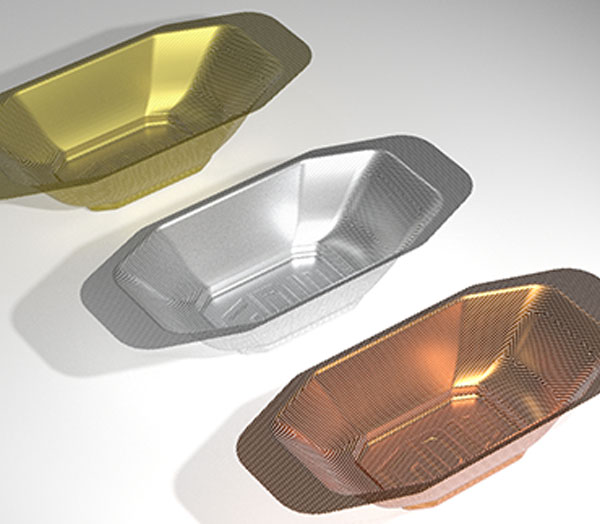

The pulp of wood, paper, or fibers is used to manufacture containers by placing the pulp in a smaller dewatering form (made from mesh or similar media) and extracting the water by vacuum. We have seen demand for these products increase as the industry moves away from plastic packaging.

Foreign Object Debris (FOD) screens prevent debris from entering moving parts. Most used in the aerospace and automotive industries, the screen is constructed from galvanized, stainless, or coated steel wire mesh formed to the shape required and bound or riveted to the formed rim.