Fluid Strainers

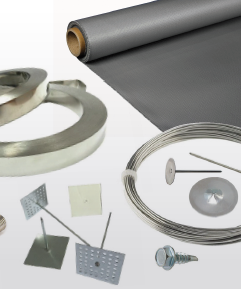

We provide a full component build of the fluid strainer assembly for pipe fittings foundries and industrial basket strainer manufacturers. Our engineers will work to determine the most cost-effective process to produce your parts. We deliver direct to the production line and can offer inventory management and replenishment systems to ensure supply chain continuity with minimal administrative effort.

Description

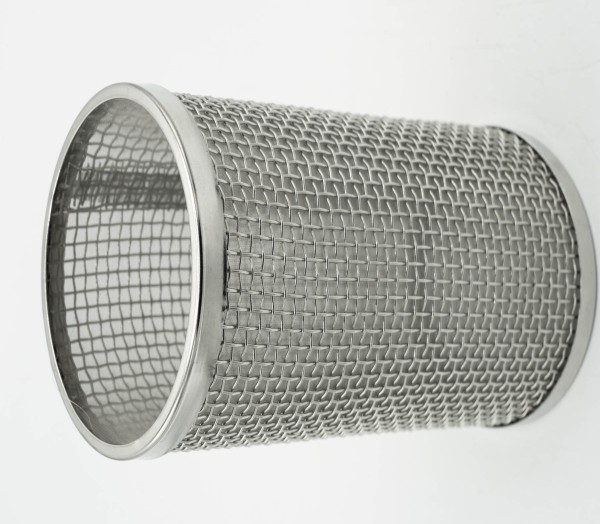

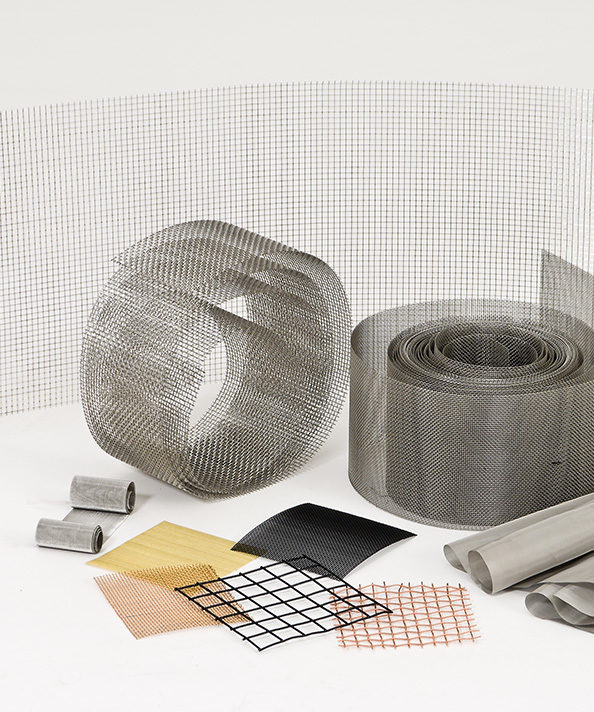

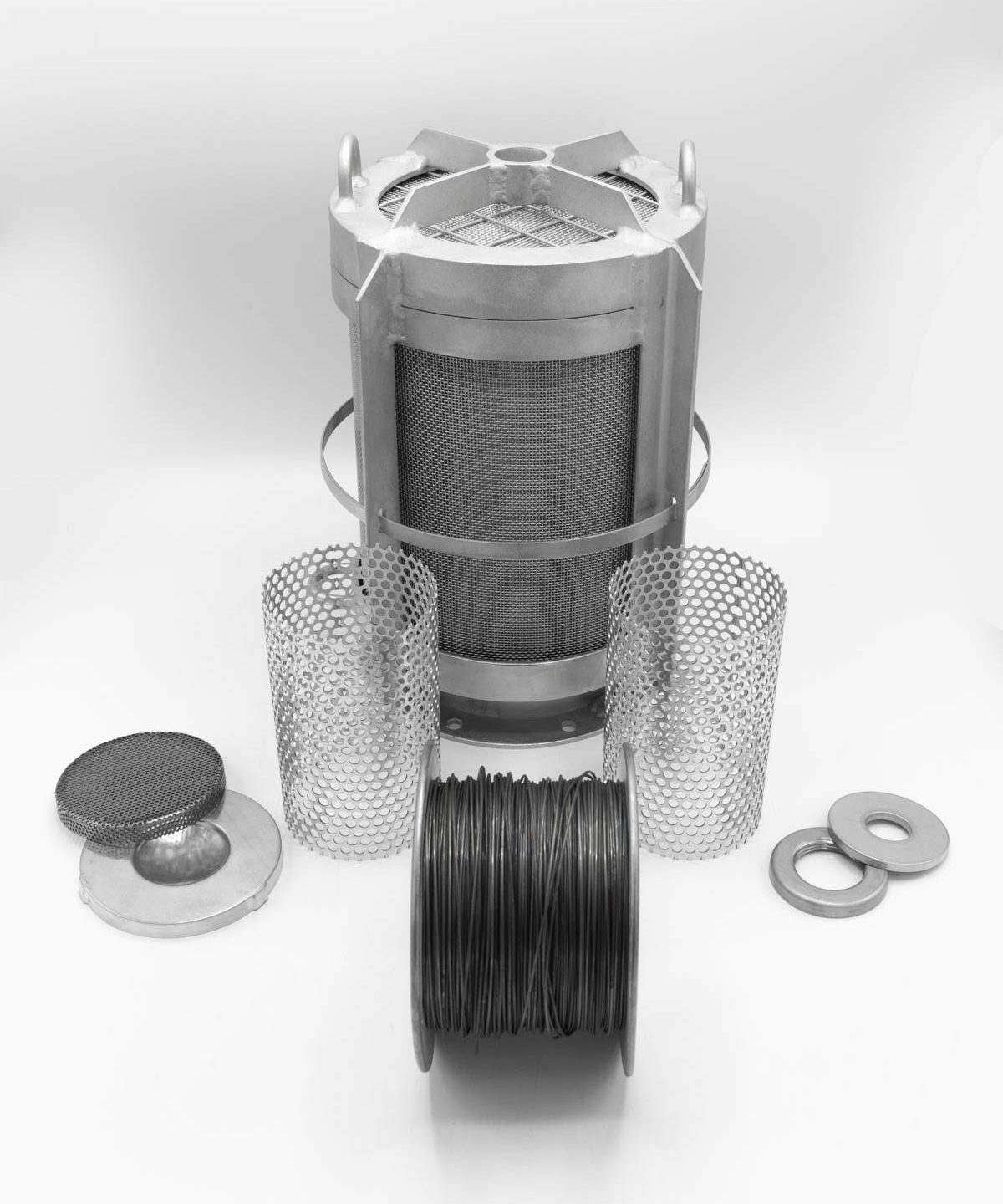

Fluid strainers are the wire mesh basket component of industrial basket strainers, valve strainers, Y-strainers, T-strainers, metal strainer filters, inlet suction strainers and other types of manufactured strainers. They catch debris in fluid lines before it has a chance to damage mechanical parts. Fluid strainers are removable from their housing to clean and inspect for debris. Rolled into cylinders, or pressed into basket form, the rigid mesh is self-supporting while finer meshes are affixed over a perforated sheet metal support structure. The mesh screen and perforated support are formed and welded into shape, then crimped, press-fit, welded, or over-molded to an endcap, flange, or mounting rim as specified by the filter strainer manufacturer.

Construction

- Typically, 40 to 100 mesh stainless steel woven wire screen; custom mesh or material optional

- Sizes range from less than a milliliter to over 100 liter

- All cutting, forming, and welding is done in-house

- CNC Laser Cutting for smaller production runs

- Custom dies for large production runs

- Tested to burst pressure to ensure against seam separation or frame separation

- Available in straight sleeve or pleated for increased surface area

Applications

We manufacture fluid and mesh basket strainer assemblies for use in fuel lines, hydraulic oil systems, process piping, bulk fluid transfer, and storage applications. Basket strainer manufacturers incorporate our mesh basket strainer components into plumbing and process piping fittings which are used in water treatment, plant operations, industrial construction equipment, mining, oil and gas extraction and transport, custom strainer, and industrial process pump applications.