Home » Industries » Oil & Gas

Oil & Gas

Our history in the Oil and Gas industry goes back for more than 30 years and uses all different types of mesh from our Dutch weaves to Tensile Bolting Cloth. Our experience along with our fabrication capabilities allows us to provide collaborative filtration solutions to our customers.

Sand Sizing

We have supplied over half a Million replacement screens to customers who process sand used in the hydraulic fracturing (fracking) process, often known as proppant sand.

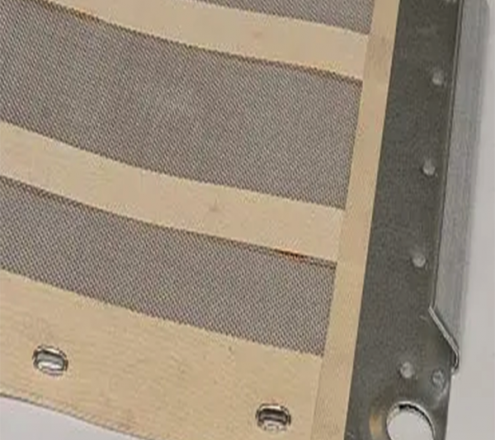

Our Sand and Mineral screens for frack sand are constructed as below:

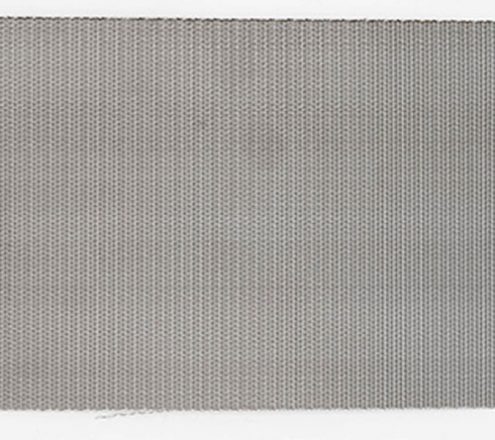

- Mesh: Tensile Bolting Cloth is used, with mesh sizes ranging from 30 to 180, depending on the gradation requirements. Mill grade is also used – some customers use this as a ‘first pass’ screening before the final sizing.

- Mesh Alloy: 316 stainless steel, which delivers a more consistent and quality weave.

- Edging Strips: Natural Cotton canvas (white color). For those customers operating in an environment greater than 215 °F, we use a heat resistant edging strip.

- In-process cleaning: (often known as de-blinding). We can provide optional rubber ball compounds offering optimum rebound, resilience and durometer to dislodge near-sized particles from mesh openings which will slow down production rates.

Many customers using OEM separator machines come to us for replacement screens. We use our deep expertise in woven mesh to maximize the gradation of a screen to exactly what is needed, rather than using a ‘cookie cutter’ approach producing screens from standard mesh. This means our customers are able to achieve higher production rates while delivering improved gradation results during their separation process.

Vertical Off-Shore Drilling : Sand Control:

We have more than 30 years supplying mesh screens for sand control to the Oil and Gas Industry, with over 20,000 screens in service worldwide. They are constructed using Dutch twill weaves and meet the requirements of ISO:17824 and API 19SS.

The mesh edges are plasma cut for safe handling and to ensure they do not unravel during fabrication, and ultrasonically cleaned to protect the metal alloy from sensitization during annealing.

The mesh is then heat treated (annealed), reducing the mesh’s susceptibility to corrosion. It becomes more ductile from the annealing process, providing better end user workability. The mesh is enclosed in a housing and is used for vertical off-shore drilling, filtering out the sand from the drilling fluid.

Cation Vessel Internals

We provide vessel internals consisting of hub & lateral or header & lateral designs along with hardware and hold downs.

Filters

We provide many different types of filters for the upstream oil and gas industries. Diesel, Gas and paraffin processing industries use different types of filters in their production (pleated filters, perforated cores, multi-layer filters). We have the capabilities to construct the housing and other different constructions and can work with you to develop your filtration solution.