Frac Sand & Mineral Screens

Sand and mineral processors require high-quality screens to optimize throughput per square foot of screening area. Screens must deliver accurate separations and high throughput. Sand and mineral screens sort many different materials, including frac sand, roofing granules, crushed limestone, and soda ash. Durable mesh sand screeners also separate abrasive materials like aluminum oxide and crushed slag.

Our durable, abrasion-resistant, sand and mineral screens meet demanding process conditions found in high-temperature and 24/7 operations.

Gerard Daniel has been making screens for frac sand and mineral producers for over 20 years. Delivering high throughput with accurate and precise separations, our screens are constructed to retrofit the most common vibratory screeners in the industry.

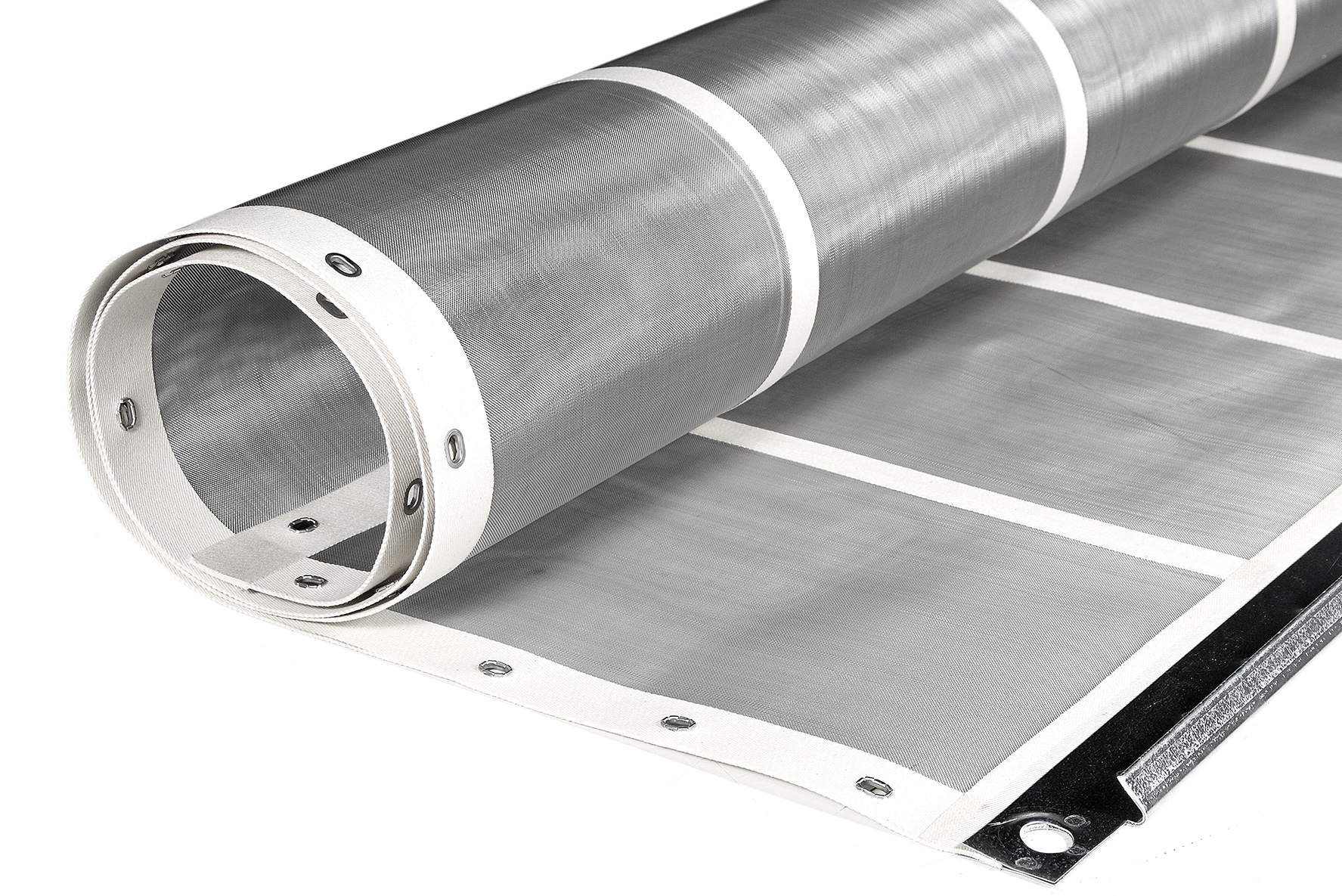

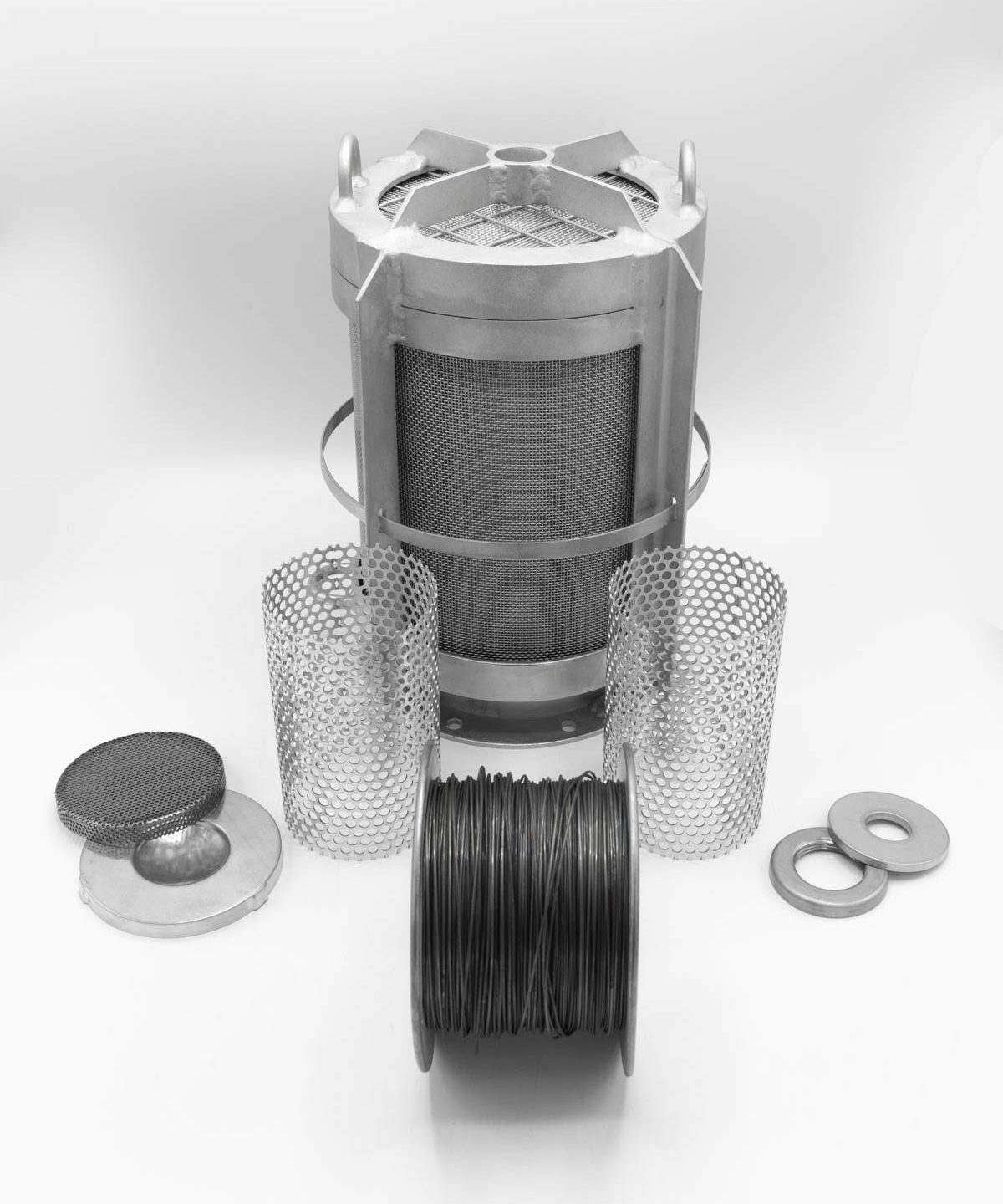

Screen Assemblies Built for Durability

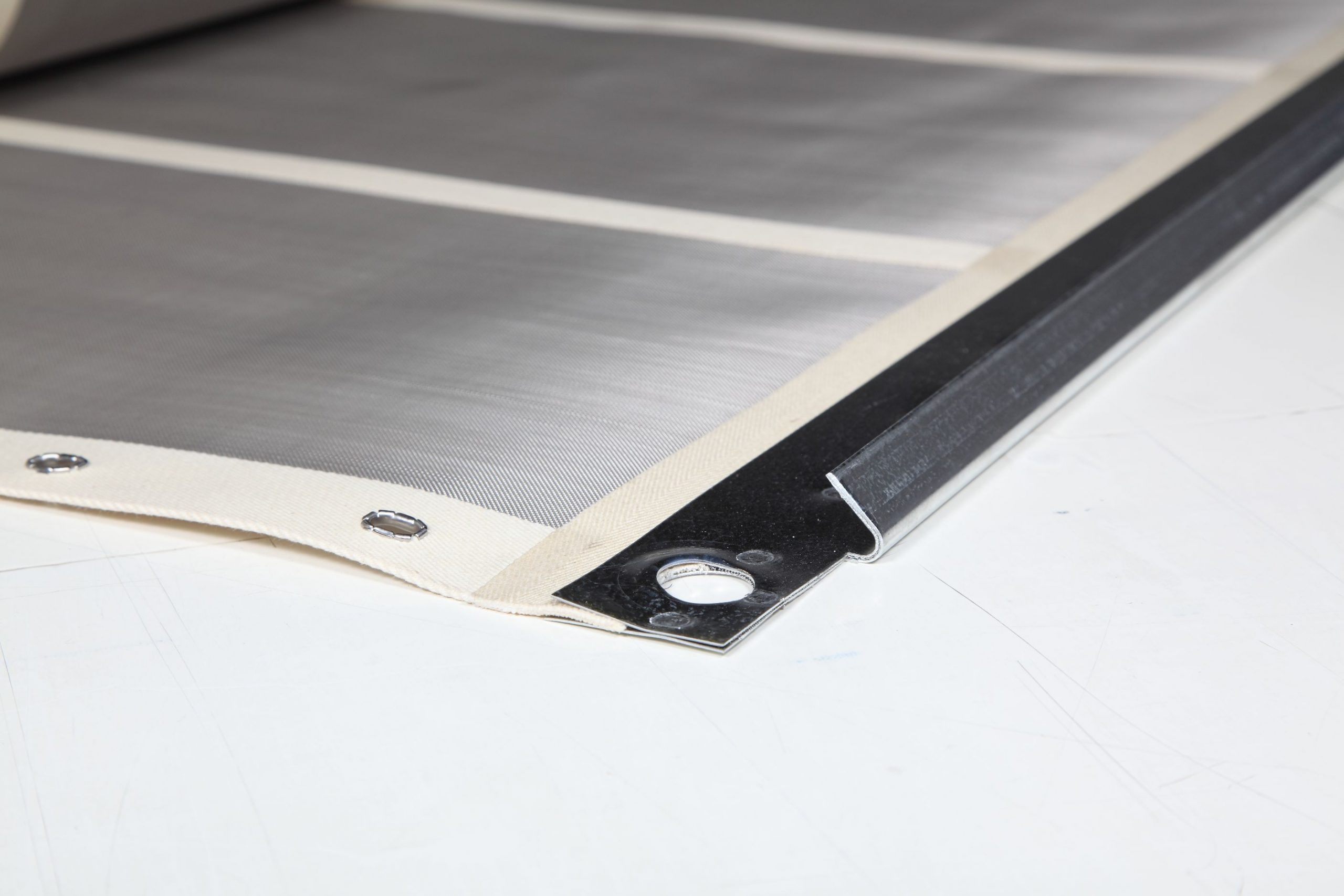

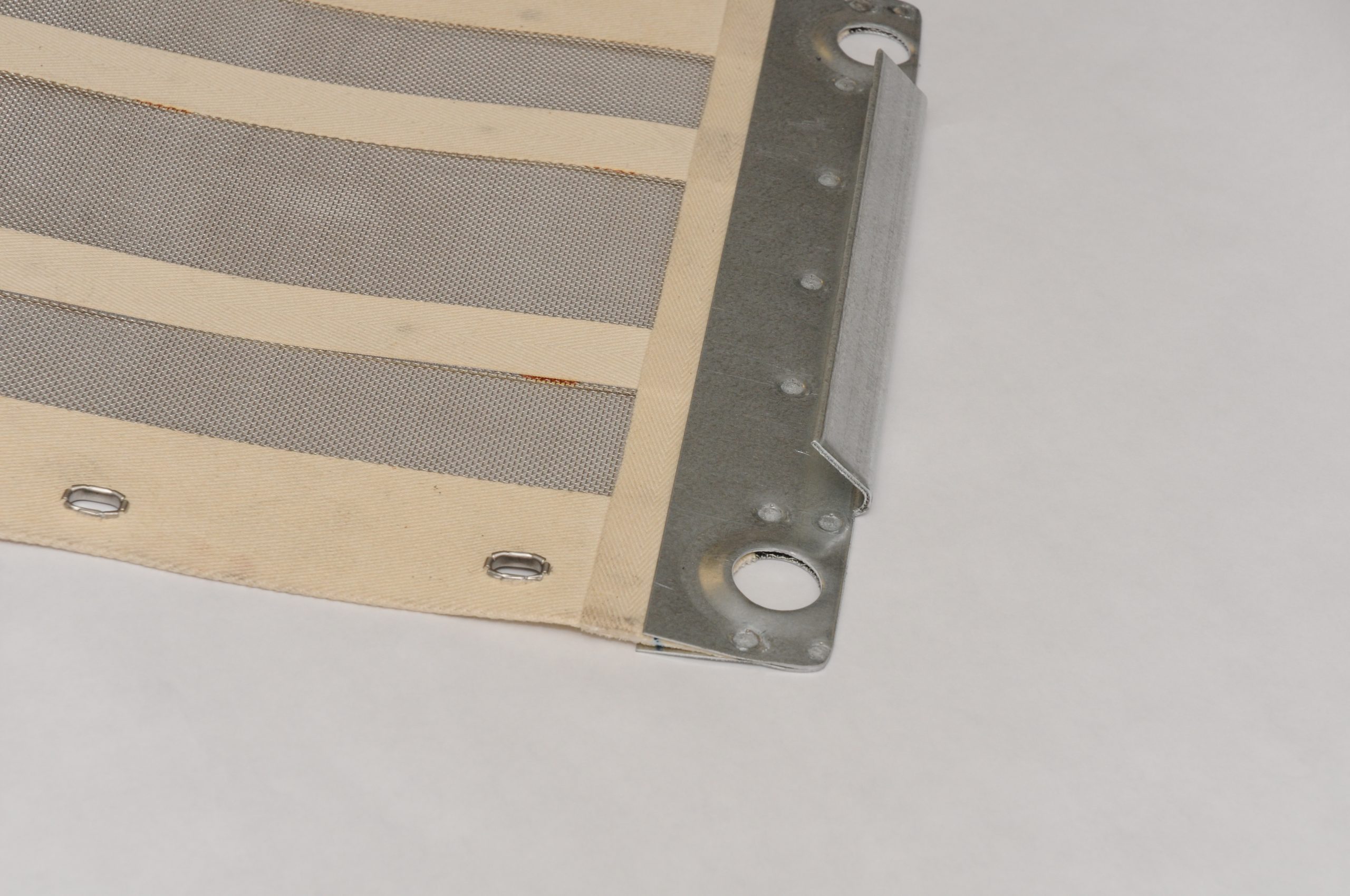

Screens are woven from 316 Stainless Steel. A metal strip is attached to one edge of the screen and a 2” natural canvas trim is attached on the other three sides. Nomex®-coated canvas is available for high-temperature applications. We can increase heat resistance and keep costs low by using Nomex on the top and natural canvas on the bottom.

Screen Specifications

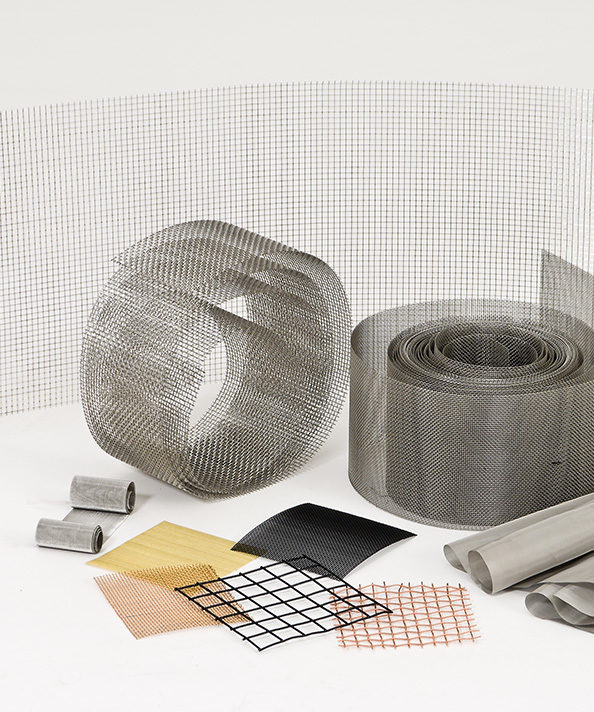

Screens are typically square/plain mesh, although other mesh types are available, depending on production efficiency requirements.

- Common screen sizes: 48”W x 89 7⁄8”L and 55 1/2”W x 146 1/2”L

- Other screen sizes available to fit any equipment brand

- Typical mesh weave sizes: 30/50, 40/70 (most popular), 70/100 μm

- Custom mesh sizes designed to increase efficiency and reduce waste

Advantages of Gerard Daniel Screens

- Mesh Expertise We have been weaving mesh for over 70 years and use our deep expertise to select a grade suitable for our customers’ applications – tweaking the grade, micron size, or wire diameter to meet the specification as necessary. Gerard Daniel screens are known for their performance and durability under the harshest conditions.

- Wear-Resistant Design Most vibratory screening machines have 5 to 7 screen decks to classify sand into different sizes for various applications. Below each screen deck is a ball deck to reduce blinding of the screen. For that reason, our screens feature center canvas strips to protect them from wear due to metal-to-mesh contact and to extend service life.

- Increased Screen Life When a machine is taken offline for screen replacement, all the screens will be replaced at the same time. We can extend your screen life by optionally adding a stronger mesh section made from mill-grade wire to the leading edge to resist abrasion from material discharge onto the deck. This increases the time between replacements and reduces the overall cost of operation.

- Custom Screens Gerard Daniel can engineer screens to match your specific profile. Customized screens, available in any weave, size, or material, will improve efficiency and reduce waste.

Outstanding Customer Service

Gerard Daniel screens are competitive on price and ready for fast delivery. We offer a CRS (Customer Replenishment System) to keep screens in stock for customers so they never have to worry about availability. Screens are on the shelf, ready when you need them, and available for immediate shipment – reducing the risk of operational downtime.