Filter Assemblies

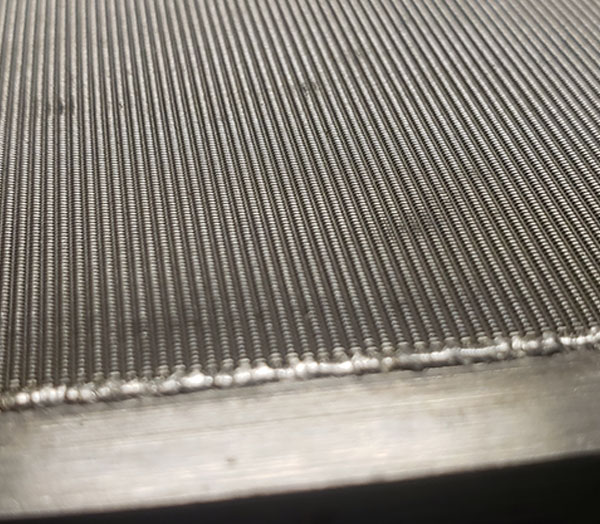

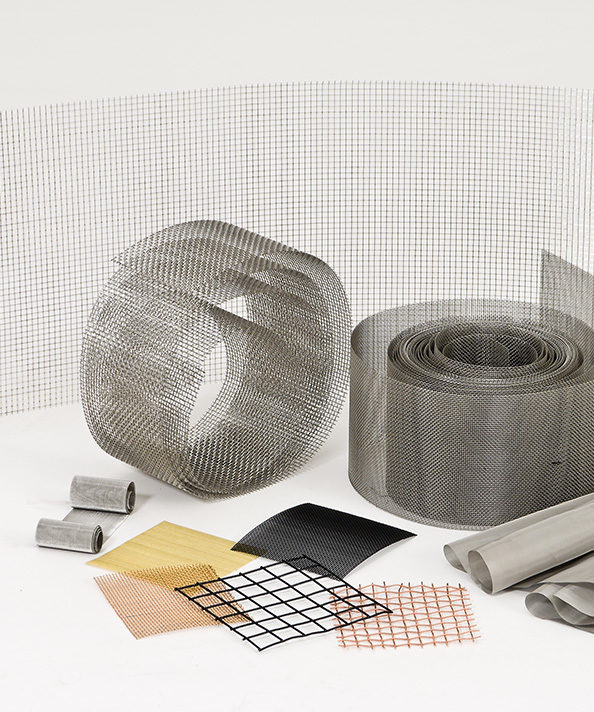

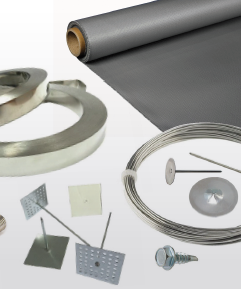

Gerard Daniel has been one of the top global wire mesh filter manufacturers for decades. Our engineers and application experts work on many different types of filters and filter systems. These types of wire mesh filters are generally a grade of micron mesh or wire cloth made in Stainless Steel, Nickel, Inconel and other high Nickel alloys. Our application experts can work with you on your filtration projects, assisting with filter design components and the selection of the correct wire mesh or cloth to meet your requirements.

Gerard Daniel is an experienced pressure leaf filter manufacturer; who provides standard circular and sectional leaf filters for pressure vessels using both filter cloth and wire mesh at 60 to 110 micron mesh for cake filtering systems.

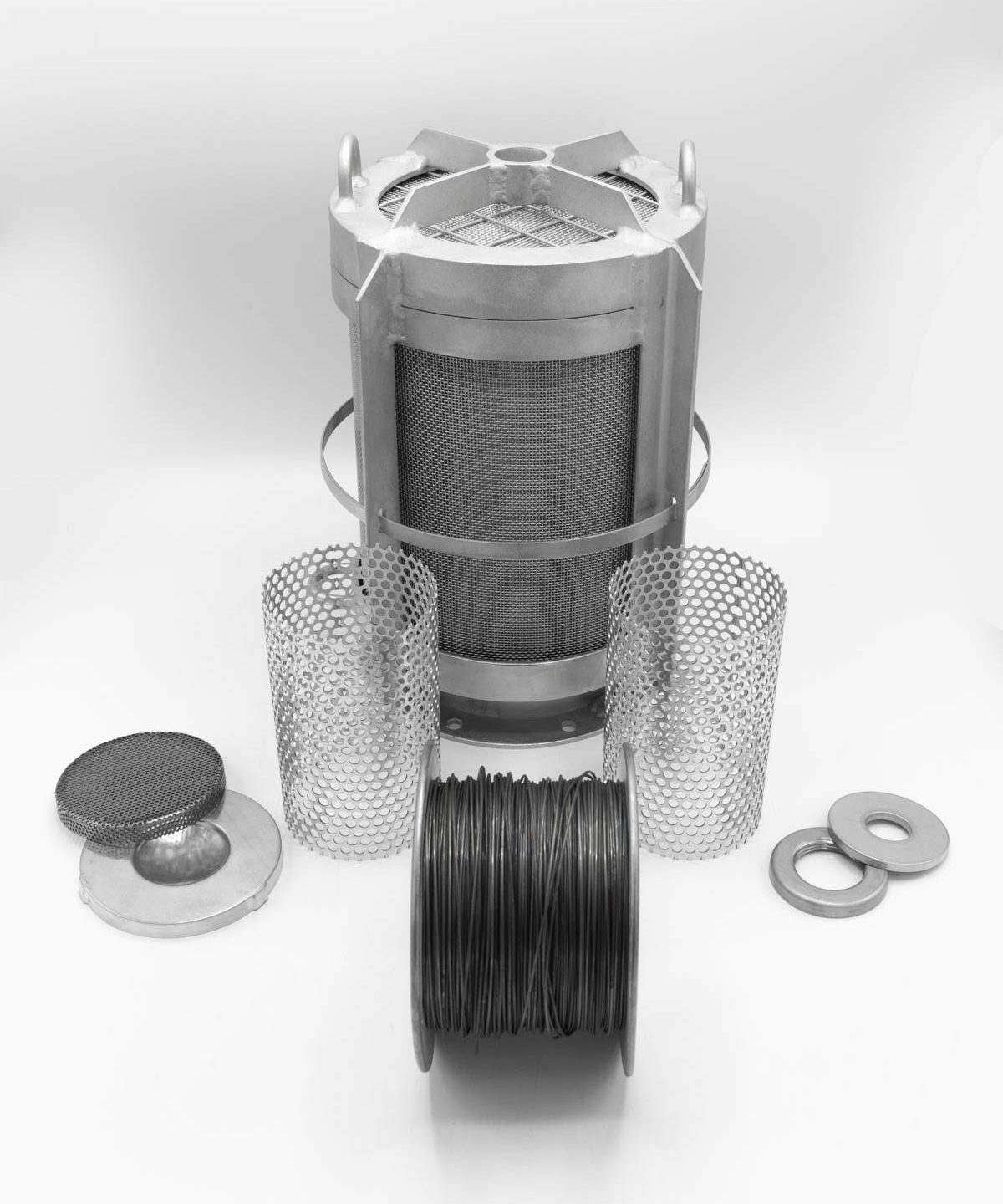

Tank Internal / Multi-Media & Vessel Filters fit in large tanks and filter water and other contaminants. Typically they are wedge wire filters, sometimes including wire mesh. We also fabricate the header, hub, and nozzles. These products provide filtration solutions for resin, multimedia, and walnut shell filters.

We supply Pleated Wire Mesh Filters mostly for fuel and oil filtration, pleating the mesh (or cloth) to allow the most amount of throughput while still maintaining a micron filtration solution, typically of 30 to 180 micron mesh. These types of filters typically have a supporting core on the inside (such as perforated or expanded metal or low mesh count square weave mesh) needed due to the pressure exerted on the pleated cloth. Pleating the cloth also gives a large surface area to catch the contaminants.

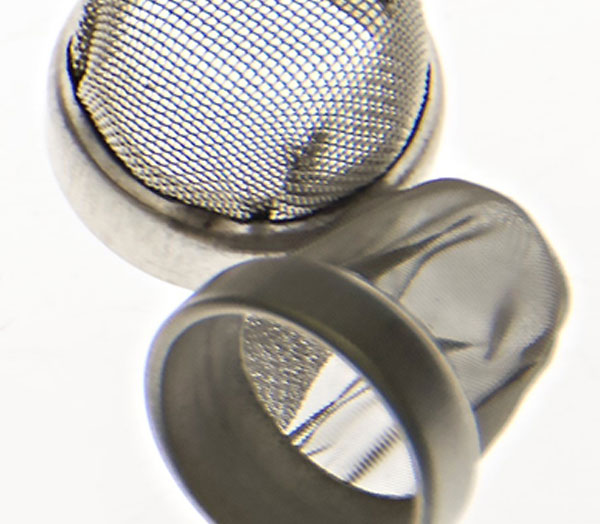

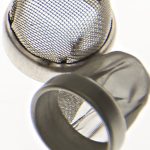

Gerard Daniel’s Inline mesh filters fit systems from leading OEMs. Sizes range from less than a milliliter to over 100 liters and 50 to 450 micron mesh for filters. Inline filters are often used as fuel injector screens; used when dealing with fuel and oil, this is typically a funnel, conical cup, or small-shaped disc which fits in the delivery pipe and prevents large particles from reaching moving parts in the engine. Also often referred to as valve filters, which are commonly used to prevent clogging within systems.

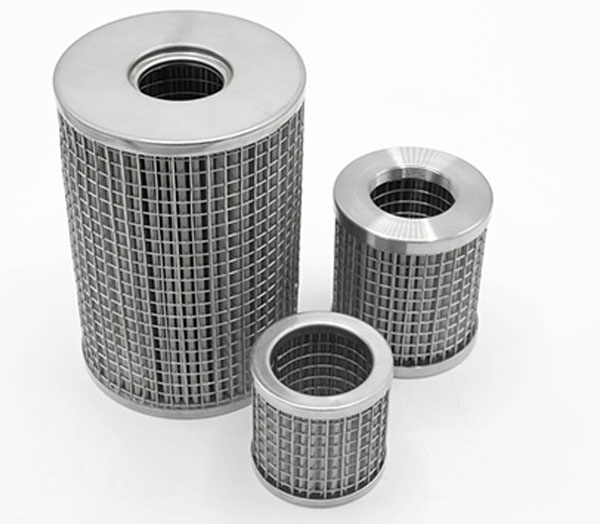

Gerard Daniel produces most sizes and types of wire mesh filters and strainers in stainless steel and other metals, including micron mesh filters in the range of 20 – 75 microns. Also we offer a wide range of secondary operations for processing, forming, as well as skilled engineering and testing to improve flow rates or capture and sort more solids. For ongoing orders, Gerard Daniel can supply inventory management and Just-in-time delivery.