Home » News » Case Studies » Case Study: Zeigler Bros.

Case Study: Zeigler Bros.

Gerard Daniel Gets Into Some Fishy Business

Zeigler Brothers was founded in 1935 as a producer of commodity feeds for poultry and livestock. As the company grew and changed hands to second and third generations of Zeiglers, they have shifted their focus to research, development, and production of nutritional feed blends for aquaculture, pets, and even zoo animals. Today they have seven manufacturing facilities – two in Pennsylvania, two in Mexico, one in India, one in Ecuador, and one in Egypt.

With a family skill set including bio engineering,

pharmaceuticals, and a PhD in Animal Nutrition, they

have positioned themselves to meet the growing

demand for aquaculture feed as fish and shrimp farming

have increasingly supplanted wild-catch fisheries.

Ziegler’s feed products are mostly produced as pellets, flakes, or powders, all of which require uniform sizes that depend on the type of animal, its stage of life, and compatibility with their respective automated feeders. To ensure this uniformity, and for other quality control purposes, the feed products must all go through vibratory screeners. They must run several screener units in various functions around the plants in order to keep up with the company’s average production rate of 50,000 pounds per day. This means that they also wear through a LOT of screens.

Convenience

To avoid costly production delays, they keep an ample supply of spare screens on hand. To save money and resources, rather than purchasing new screens to replace their worn ones, they send the worn screens back to Gerard Daniel for refurbishing and rescreening instead. Customers further afield usually choose to ship their screens, but at just 20 miles apart, the Zeigler Bros. main facility is able to drop off and pick up their screens at Gerard Daniel themselves for additional savings.

“We go through so many screens here. Gerard Daniel stays on top of rescreening and keeps us going with a ready supply of fresh screens, so I don’t even have to worry about it. Changing screens is easy, too. With just a few tools and a little time you’re back up and running, good as new!”

Bryan Little, Maintenance Department

Rescreening Process

When Gerard Daniel receives screens that are worn or damaged, they undergo the following process:

- Remove the rubber perimeter gasket from the frame ring.

- Inspect the ring for irreparable damage

- Cut most of the old screen mesh away from the frame ring.

- Remove all the old epoxy embedded with wire mesh remnants using a special abrasive-free cleaning process that does not grind down or impregnate the surface of the stainless steel frame with impurities that would otherwise compromise proper adhesion of the new epoxy.

- Apply a new circle of wire mesh to the now like-new stainless frame ring.

- Pretension the new mesh and epoxy it to the frame ring just as they do with new screen frames.

- Apply a shock-absorbing bead of silicone around the interface of the mesh, epoxy, and frame ring to extend screen life, just as they do with new screen frames.

- Clean and reinstall or replace the rubber perimeter gasket depending on its condition. Reassemble sandwich screens with balls and lower tray when applicable.

- Recycle the spent mesh.

- Repackage the refurbished pretensioned screen ring in a protective cardboard box for pick-up by the customer or shipping service.

Savings

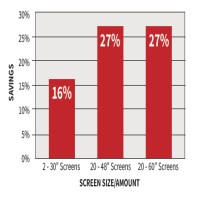

There is no minimum order for rescreening but shipping more screens at once is more cost effective. The biggest savings can be realized by customers like Zeigler Bros., with lots of separator machines and a predictable rate of screen replacement, by sending in dozens of screens at the same time. For most mesh types, a batch of refurbished screens costs the customer about 25% less than the same number of new screens. Gerard Daniel calculated that the “Magic Number” of screens to refurbish at once to maximize savings is 20 or more.

“Our customers are delighted when they realize they can save over 25% on their new screens. Our proprietary cleaning and preparatory line ensures that the screens operate as new when they are delivered to the customer.” – Ron Hoke, Gerard Daniel Operations Manager

Rescreening is available not just for owners of Gerard Daniel screener units. Vibratory screeners are quite standardized from one manufacturer to the next, so Gerard Daniel is able to offer rescreening for any separator manufacturer’s screen rings. Rescreening makes even more sense as stainless steel prices continue to climb.

Gerard Daniel Expertise

With over 70 years of experience in wire mesh solutions, our applications engineers collaborate with our customers to improve performance and reduce cost in a wide range of separation applications in food and beverage, agricultural, and industrial processing. With multiple operations in the US as well as Canada and Ireland, Gerard Daniel Worldwide is a leading provider of mesh, filtration and separation solutions used in a broad array of critical OEM and MRO applications. Increase your productivity and lower your production costs by consulting with the screening experts at Gerard Daniel Worldwide.