Home » Wire

Wire

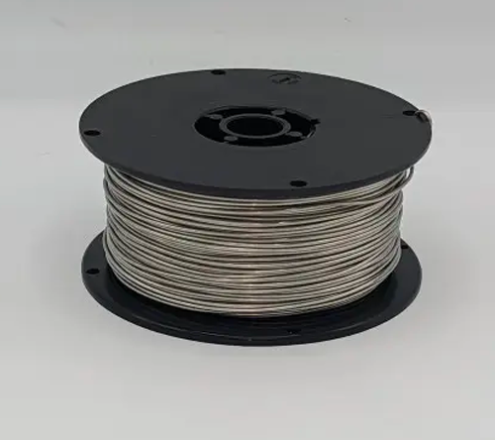

We can provide wire products for many different applications in corrosion-resistant and high temperature alloy wire, Stainless steel and Nickel alloys. We supply sizes ranging from .05” to .625” in rounds and up to .375” in squares and hexes, in tempers annealed through full hard. We offer a variety of packaging, including coils, spools, reels and straightened and cut in lengths up to 12 ft.

Wire Alloys

| Alloy | Sub-type |

| Stainless Steel | 302,304/304L, 305, 310, 316/316L, 317/317L, 321, 330, 347, 410/416/430, 17-4Ph/17-7Ph |

| Nickel | 200, 201/205, 800, Alloy 400, Alloy 600, and Alloy X750 |

Wire Applications

- Antenna Wire

- Belt Wire

- Brush Wire

- Dental Wire

- E.P.Q Wire

- Filter Wire

- Forming Wire

- House Wire

- Knitting Wire

- Medical Wire

- Orthodontic Wire

- Pin Wire

- Rod Wire

- Safety Lock Wire

- Shaped Wire

- Spring Wire

- Tag Wire

- Tie Wire

- Weaving Wire

Wire Specifications

We meet the following specifications:

- MS20995C

- MS20995N

- MS9226

- AMS5689

- AMS5643

- MS20995CY

- MS20995NC

- 302 Condition A

- 304 Condition A

- 305 Condition A

- 316 Condition A

- 321 Condition A

- QQ-W-423

- QQ-W-390

- QQ-N-281

- Alloy 600 Annealed

- Alloy 600 Oxide Coated

- Alloy 400 Annealed

- Aluminum 5056

- Copper QQW-343 Type 5