Home » News » Case Studies » Case Study: Industrial Vehicle Design

Case Study: Industrial Vehicle Design

Gerard Daniel Collaborates on a Winning Grille Design for Major Truck Maker

In March 2015, a Gerard Daniel business development executive working with a plastic molding supplier to a major tractor-trailer cab manufacturer began discussions on the design of a front grille with a wire mesh profile for a new truck model.

The opportunity came up in discussions regarding second-hand comments from a competitive mesh provider who had advised the customer that the grille was not manufacturable in its present design. Inspired by the challenge, Gerard Daniel initiated contact with the truck maker’s product development team to discuss a profile that would meet their needs. The opportunity came up in discussions regarding second-hand comments from a competitive mesh provider who had advised the customer that the grille was not manufacturable in its present design. Inspired by the challenge, Gerard Daniel initiated contact with the truck maker’s product development team to discuss a profile that would meet their needs.

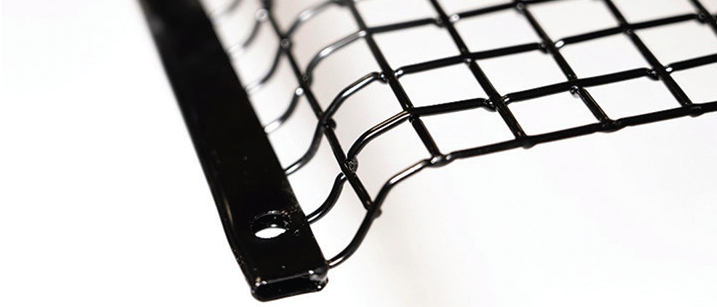

The truck maker’s team specified that the mesh insert needed to fit the plastic cab surround to within 3 mm on each side and it required a safe edge, meaning no protruding wires, without restricting airflow, so a channel frame was not permissible.

Gerard Daniel engineers worked with the customer’s product development team and suggested adjustments to their original design to make it manufacturable. Thus, the three-dimensional shapes indicated in the design were reconfigured to fit within specified tolerances into the envelope of the grille surround, while maintaining perpendicularity with respect to the grille’s square openings.

After the design alterations were approved, the truck maker created a 3-D model based on Gerard Daniel’s concept which defined the manufacturing parameters, identifying the number and size of openings across the width and height of the grille’s surface area. Gerard Daniel determined how to terminate the grille on an edge wire to avoid exposing any wire ends. A u-channel was incorporated along the top and bottom edges, which eliminated the potential for airflow interference. When the Gerard Daniel team presented their prototype to the customer, they were impressed.

A letter of award was delivered to Gerard Daniel in September 2015, 6 months after initial contact. The part made for the PPAP submission and first approval was delivered to the manufacturer’s assembly plant in March 2016. The customer’s team took one of every component on the truck’s hood and built the cab prototype on their floor. Once the prototype was assembled, the customer’s team was pleased with the grille’s appearance, fit and finish. In fact, Gerard Daniel’s component was one of the few that didn’t require multiple adjustments. Full production began in January 2018, nearly three years after first contact. During that time, Gerard Daniel built the tooling and engineered the weaving and manufacturing cells to prepare for production.

Prior to manufacturing, Gerard Daniel made a low-cost pre-fixturing phenolic tool in-house to form the prototype for first article approval and produced and delivered it approximately four weeks after initial concepts were approved. Only after the part’s profile was fine-tuned did Gerard Daniel commit to tool steel stamping dies. Once in production, the phenolic tool served as a check fixture to ensure every finished grille met the customer’s specifications for mounting hole alignment, which were required to fit within 1 to 1.5 mm tolerances over more than a dozen points. The go/no-go fixture was necessary because the 3-D wire form is otherwise unmeasurable in conventional terms before mounting on the truck, for which the fixture is a proxy.

Production involves more than eight individual steps that come together to make each finished grille.

- Precrimped wire is first woven to form the basic mesh platform

- Locating and mounting hardware is flush mounted and welded to the mesh assembly

- Several other intermediate steps take place before the assembly is pressed into its finished profile

- After inspection, each grille is precleaned and powder coated; then it passes through a final inspection using the original phenolic die before being shipped

According to Steve Crooks, Gerard Daniel’s Vice President of Business Development, “We have solid skills in the pre-crimp mesh business, but we also bring a lot of manufacturing expertise when it comes to working with wire mesh. We collaborated with the customer’s engineers in the development of the part to define what could and couldn’t be fabricated easily and practically with wire mesh. There was quite a bit of back-and-forth to come to terms with a design that satisfied their needs while making it manufacturable.”

When parts were first delivered to the customer’s assembly plant, Gerard Daniel shipped product in wooden crates. Since then, the company developed a returnable plastic container system that not only reduced cost but eliminated environmental waste.

Gerard Daniel is a primary wire mesh solutions provider for the industrial and commercial vehicle market. With over 70 years of experience in wire mesh solutions, our applications engineers collaborate with our customers’ design teams to improve performance and reduce cost in a wide range of applications including air vents, grilles, and debris screens, plus numerous in line filtration and strainer assemblies in fuel systems and hydraulics. With multiple operations in the US as well as Canada and Ireland, Gerard Daniel Worldwide is a leading provider of mesh, filtration and separation solutions used in a broad array of critical OEM and MRO applications. Please reach out if you would like to learn more about our capabilities.