Fiber Molded Products: Why Choosing the Correct Porous Media Is Essential to Efficient Production

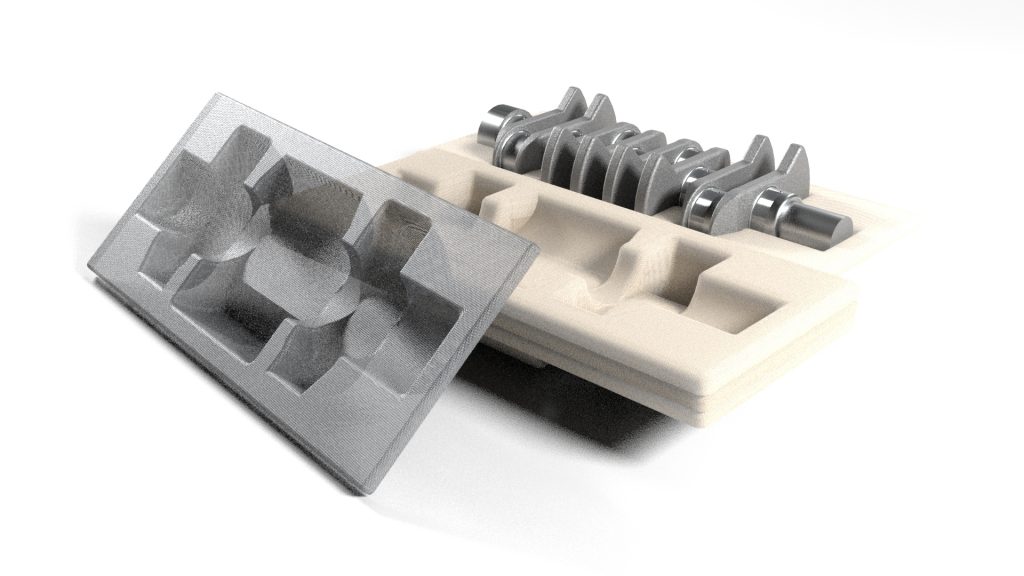

Molded fiber production began over 100 years ago as a protective and efficient way to package more delicate goods such as eggs and light bulbs. Fiber molds can be formed to almost any shape and are able to absorb shock and avoid damage to the product. Now fiber molded products (sometimes known as pulp molded products) can be seen around us every day, from restaurant to-go containers to protective packaging in electronics boxes. As more companies move towards more sustainable solutions for their business, production rates of these products have continued to increase.

The techniques used to create pulp molded packaging have evolved over the years, however for many manufacturers, one of the essential steps in creating a successful pulp molded product is producing the forming wires used to shape and dewater that product. In this part of the process, selecting the best material for the job is key. There are four areas that need to be considered – Alloy Selection, Media Type, Opening Size, and Heat Treatment.

Benjamin Henneberger Made this on 8/4/2021

Alloy Selection

The properties of certain alloys cause them to produce different results when wire forming. Two of the most common alloys used in the construction of the molds are Stainless Steel and Brass Alloys.

| Alloy | Advantages | Disadvantages |

| Stainless Steel | • Strength • Corrosion resistance (varying degrees) • Product range (coarse to fine) • Availability | • Work hardening • More challenging to anneal • Challenging to form multi-pocket wire forms • Doesn’t transfer heat as well |

| Brass and Brass Alloys | • Transfers heat easily • Malleable • Works well in perforated and expanded • Less embrittlement from forming • Good thermal conductivity | • Product availability • Media type selection range • Not as rigid • Less strength |

Benjamin Henneberger Made this on 8/4/2021

Media Type

When it comes to media selection there are many types, however, the most frequently used media types are:

Mesh

Mesh is the most common as it provides the most versatility in manufacturing deep drawn forms. This is due to the natural elongation of the wire and the flexibility of a woven product allowing it to easily form intricate shapes and crevices. It is available in many configurations (alloy/thickness/opening) offering the highest levels of filtration or the highest open area.

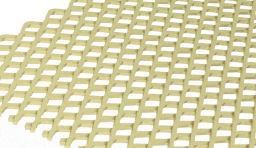

Perforated

Perforated metals have a great strength-to-weight ratio, which allows for small holes with significant open areas while still being strong enough to be self-supportive. This media provides good thermal conductivity.

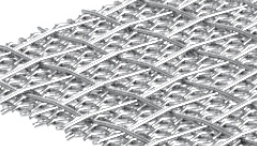

Expanded

Expanded metal is a versatile product that can combine small holes and higher open areas than can be achieved with perforated metal. While not as strong, the opening patterns allow the media to take on some of the more difficult shapes required for the molded fiber industry.

Multi-Layered Sintered

Multi-Layered Sintered metals can extend the life of a wire form by using two or more pieces of mesh and metallurgically bonding them together. Multi-layer laminates use a fine mesh for the filtration properties and a coarse mesh for the durability of the wire form, prolonging the life. Sintered media is more durable and is able to withstand the vacuum process longer

Benjamin Henneberger Made this on 8/4/2021

Mesh Count and Opening Size

If the appearance of the fiber molded product is critical, a higher mesh count should be recommended. A higher mesh count means more wires per square inch and a smaller open area between the wires. This will give a smoother surface of the fiber mold. For other products, the end customer may not be worried about the smoothness of the outside of the product and therefore a bigger opening with a greater diameter mesh can be used. This will give it a longer lifespan.

A higher mesh count means more wires per square inch and a smaller open area between the wires…

Gerard Daniel

Benjamin Henneberger Made this on 8/4/2021

Heat Treating (Annealing)

Annealing can be an essential step in the preparation of the media to increase the malleability as it enters the drawing process. Proper annealing practices will eliminate work hardening created during the weaving operation, allowing the top tool to draw down the media into the forming tool base without it folding, tearing, or ripping. Depending on the type of media, depth of the form, and tightness of the radii, it may be annealed again during production.

Benjamin Henneberger Made this on 8/4/2021

Media Selection Impacts the Bottom Line

Choosing the right media directly impacts the quality of the wire forms produced and their lifespan. This in turn will directly affect the bottom line of the pulp mold manufacturer. While many have the capacity to produce their own wire forms, there is the potential for this process to turn into an uncontrolled cost center if it’s not carefully managed. One way to do this is by working in partnership with a company specializing in porous media, wire forms, and deep-drawn forming. This can help pulp molding manufacturers reduce cost, save time, re-allocate manpower, and ultimately focus on the production of pulp molds for their customers.

Gerard Daniel is a leader in wire cloth, deep-drawn products, and associated wire mesh components. Throughout the years, Gerard Daniel has grown in size, geographic reach, manufacturing capability, and product range with six ISO 9000 certified manufacturing and service sites throughout the United States, Canada, and Europe. They have a well-established just-in-time customer delivery program and supply many sectors, including the packaging, food, and beverage industries.