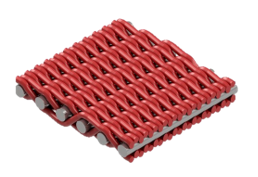

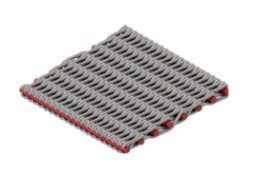

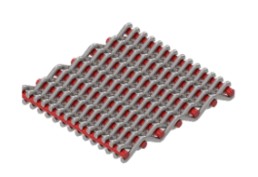

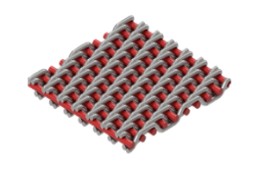

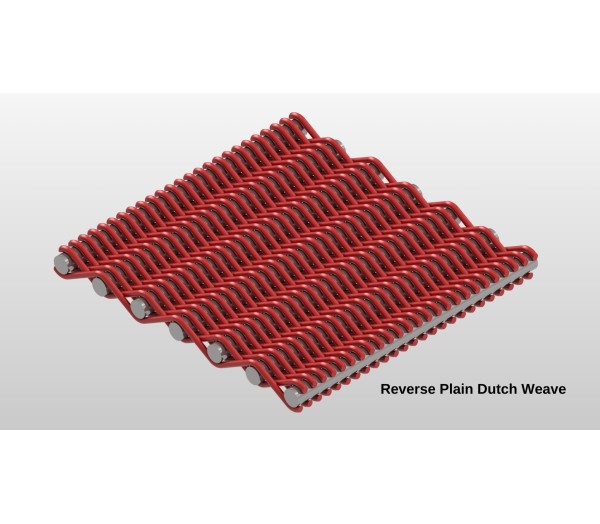

Reverse Plain Dutch Weave

“Reverse” describes the fact that the warp wires of this weave are relatively thin and the shute wires are thick – in other words, the exact opposite of the standard dutch weaves. The reverse dutch design produces precisely defined pore openings that run under an angle to the surface of the mesh. The high number of warp wires increases the active filtration cross section. Depending on the specifications, this can be approx. 21 – 25%. The reverse dutch weave is available in “heavy” and “light” versions. The light version has a special wire combination that increases the active filtration cross section to 25 – 38%.

| Mesh Per Inch Warp x Shute | Wire Diameter, Warp in. (mm.) | Wire Diameter, Shute in. (mm.) | Porosity (%) | Thickness in. (mm.) | Weight, Stainless Steel lbs./sq. ft. (kg./sq. m.) | Micron Retention |

| 66×18 | 0.012 (0.300) | 0.016 (0.400) | 66 | 0.042 (1.07) | 0.45 (2.22) | 200 microns |

| 84×25 | 0.013 (0.320) | 0.016 (0.400) | 49 | 0.043 (1.09) | 0.63 (3.09) | 150 microns |

| 130×30 | 0.008 (0.200) | 0.018 (0.450) | 53 | 0.032 (0.82) | 0.58 (2.82) | 100 microns |

| 130×35 | 0.008 (0.200) | 0.016 (0.400) | 56 | 0.030 (0.75) | 0.55 (2.70) | 80 microns |

| 175×40 | 0.006 (0.150) | 0.014 (0.350) | 58 | 0.022 (0.55) | 0.46 (2.24) | 104 microns |

| 175×45 | 0.006 (0.150) | 0.013 (0.320) | 56 | 0.024 (0.62) | 0.44 (2.16) | 100 microns |

| 175×50 | 0.006 (0.150) | 0.012 (0.300) | 53 | 0.022 (0.56) | 0.44 (2.14) | 60 microns |

| 290×60 | 0.004 (0.090) | 0.009 (0.230) | 50 | 0.016 (0.40) | 0.28 (1.36) | 50 microns |

| 290×74 | 0.004 (0.090) | 0.008 (0.200) | 52 | 0.014 (0.36) | 0.26 (1.27) | 40 microns |

| 625×104 | 0.002 (0.042) | 0.006 (0.150) | 55 | 0.009 (0.24) | 0.18 (0.87) | 30 microns |

| 625×106 | 0.002 (0.042) | 0.006 (0.140) | 56 | 0.009 (0.23) | 0.17 (0.85) | 25 microns |

| 625×132 | 0.002 (0.042) | 0.005 (0.130) | 48 | 0.008 (0.20) | 0.17 (0.84) | 17 microns |

| 625×134 | 0.002 (0.041) | 0.005 (0.130) | 48 | 0.001 (0.02) | 0.17 (0.85) | 14 microns |

| 720×150 | 0.001 (0.035) | 0.004 (0.100) | 45 | 0.006 (0.16) | 0.12 (0.60) | 14 microns |

| 720×150 | 0.001 (0.035) | 0.004 (0.112) | 48 | 0.007 (0.17) | 0.13 (0.65) | 15 microns |

| 912×154 | 0.001 (0.028) | 0.004 (0.090) | 57 | 0.006 (0.16) | 0.10 (0.49) | 13 microns |

| 1005×200 | 0.001 (0.025) | 0.002 (0.050) | 63 | 0.004 (0.10) | 0.06 (0.28) | 10 microns |

Alternative Micronic Weaves