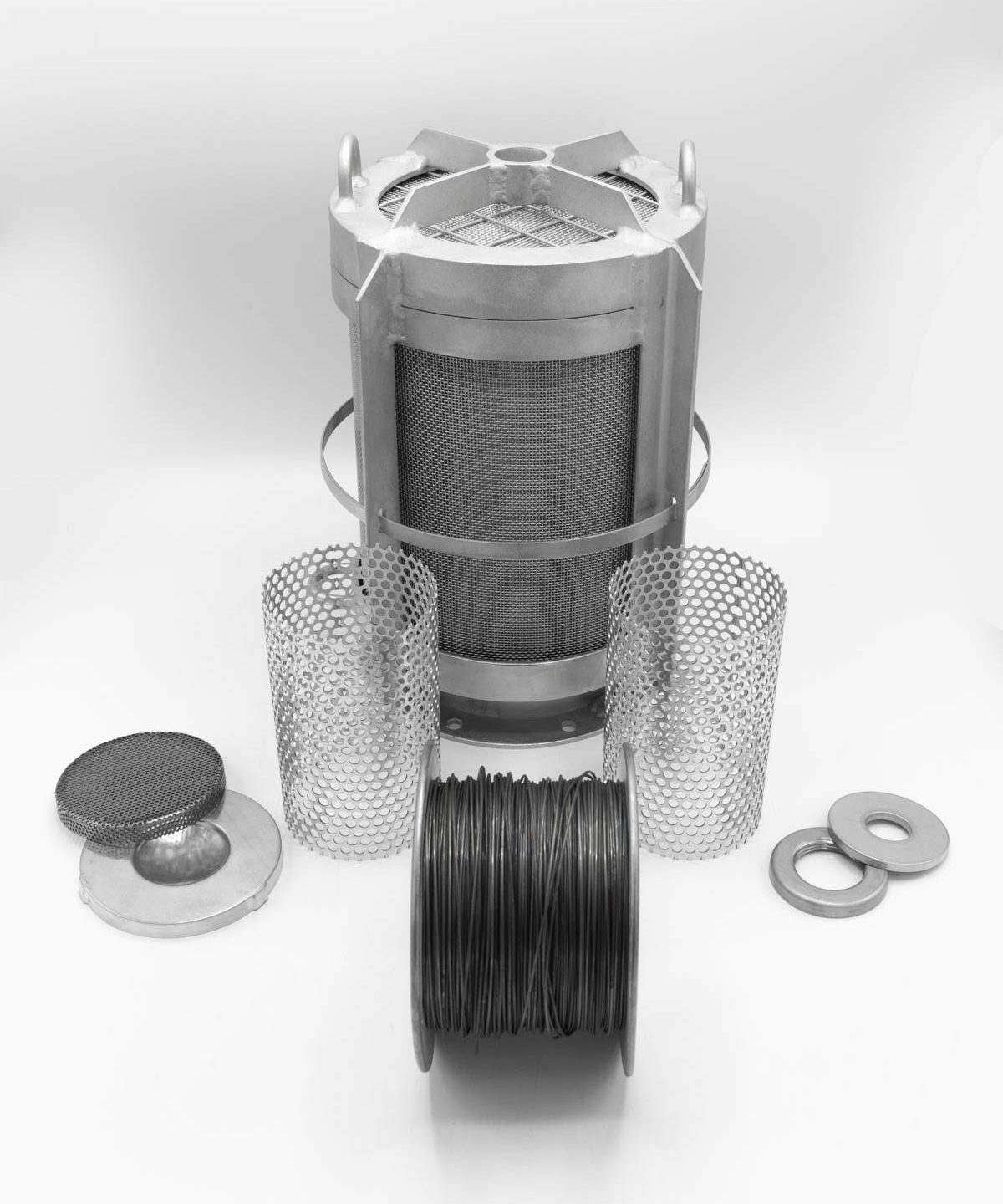

Deblinding Slider Rings & Clusters

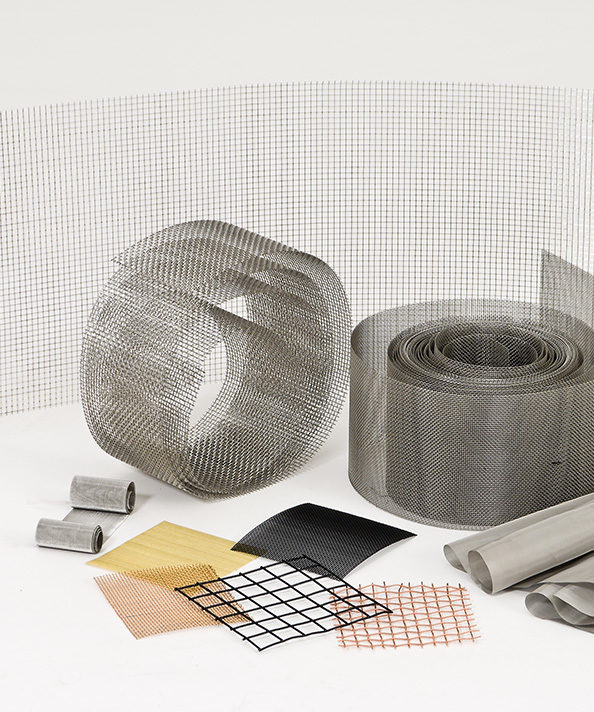

Deblinding is a common challenge with both wet and dry product screening in separator machines. Near-size particles either get trapped in the mesh, or they build up on the wires, causing caking. Once screen openings are blocked, production suffers. Sliders, by themselves or in combination with balls, can help to alleviate this problem.

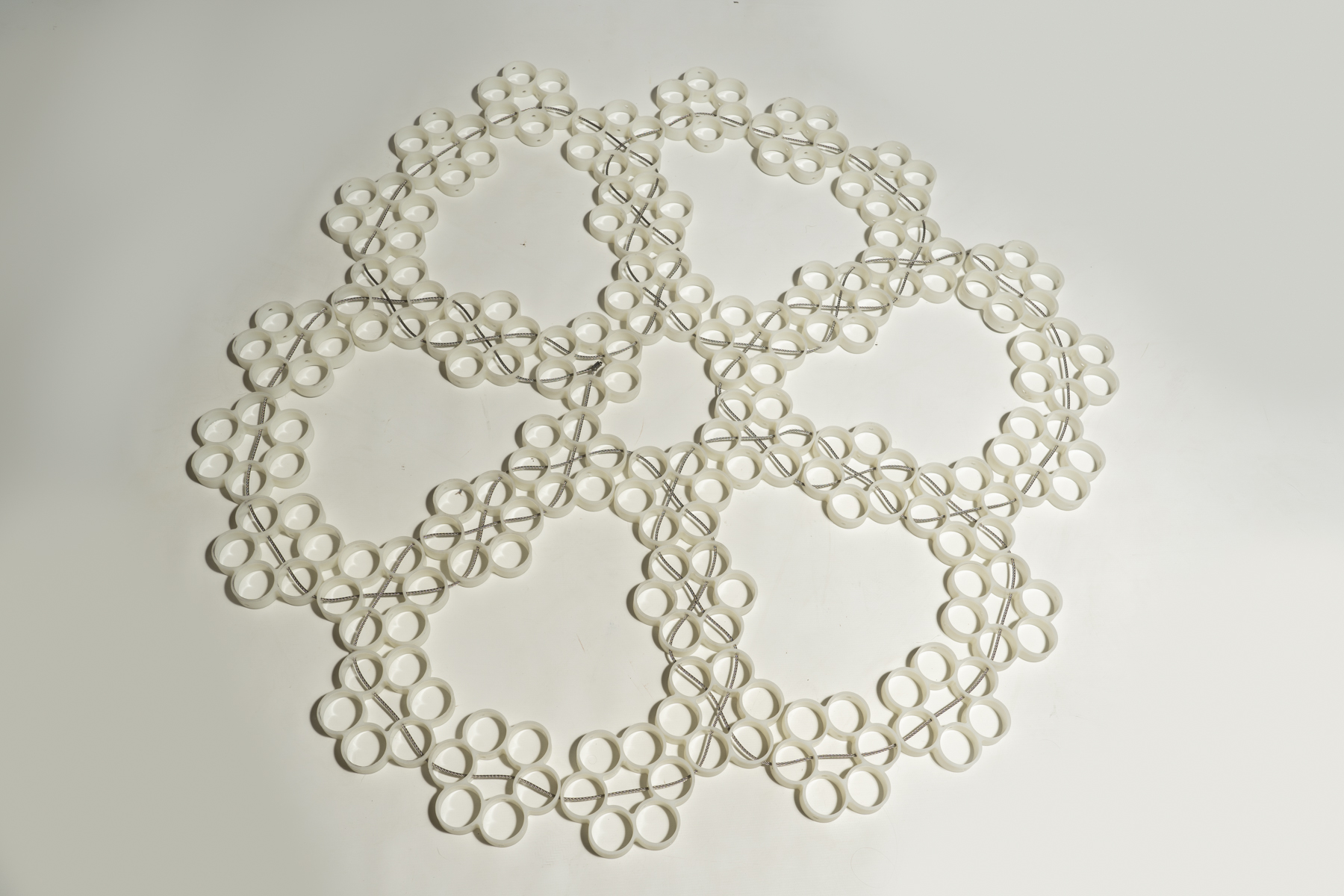

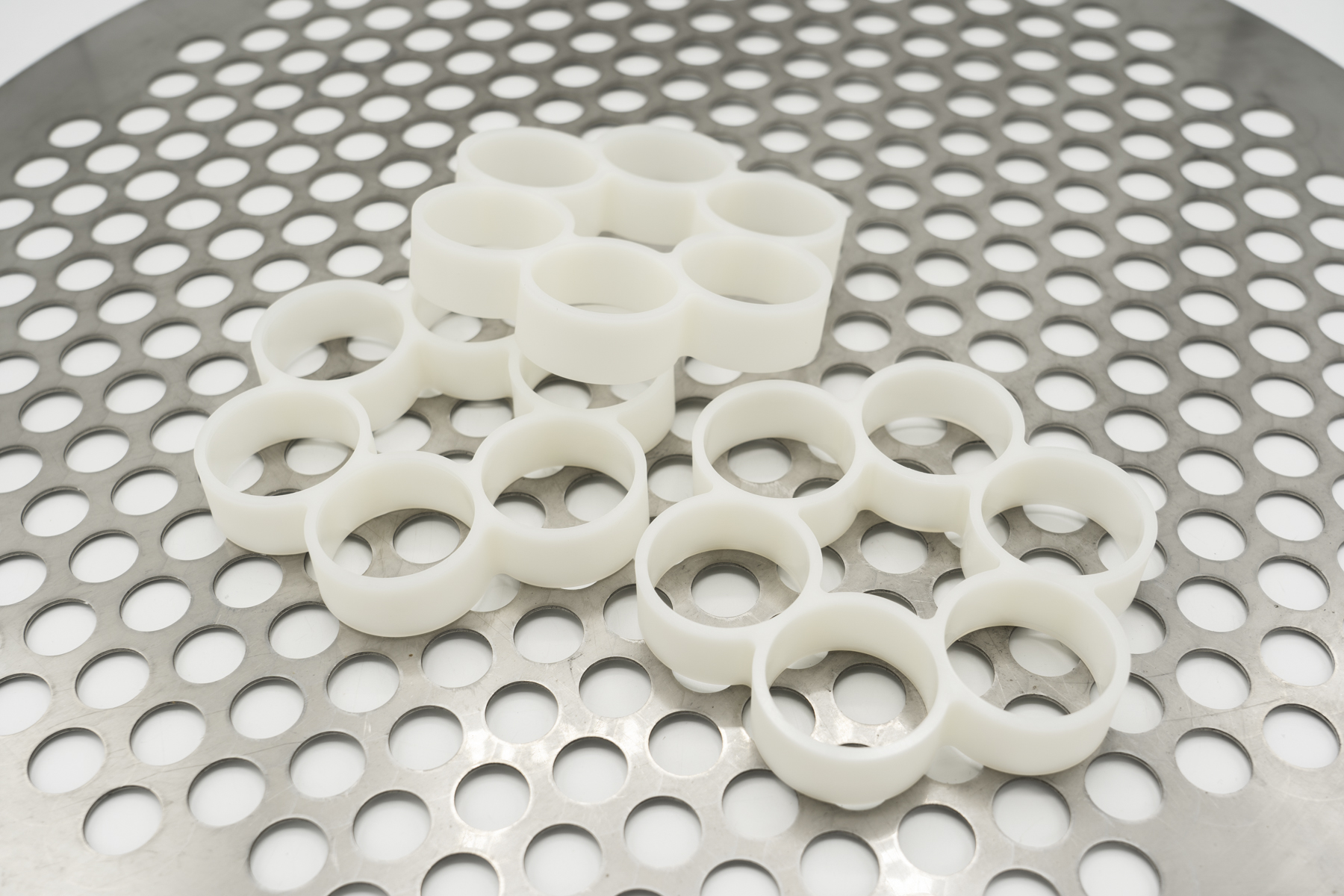

Due to their larger size, slider clusters (sometimes called honeycombs) are often used in larger-diameter screening. While the weight of slider clusters can increase their impact on the screen, the presence of fewer clusters also reduces the overall impact.

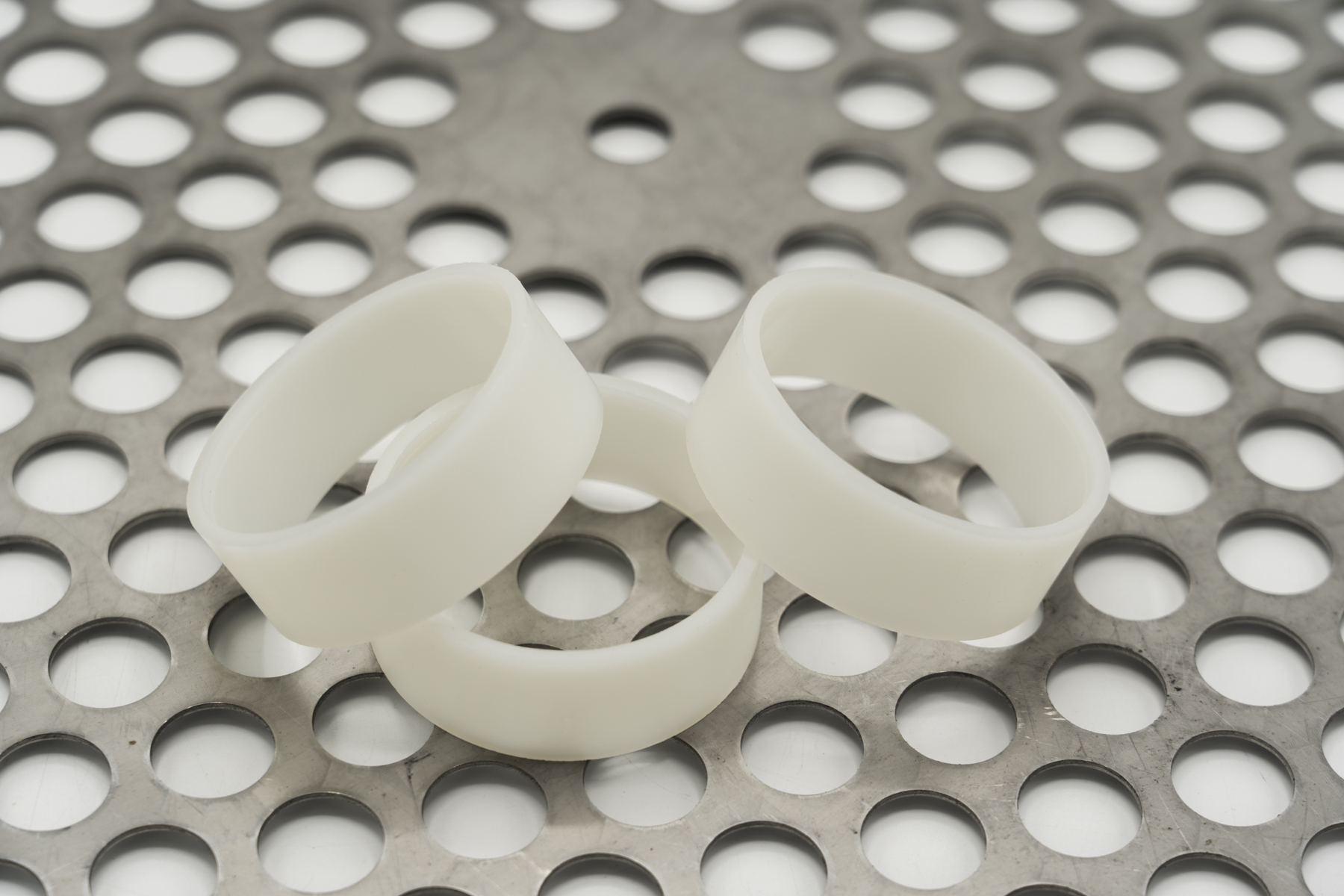

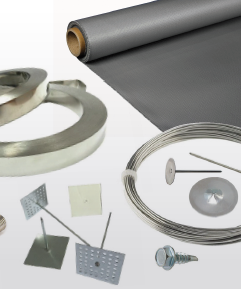

There are times when sliders deliver more effective deblinding than balls. For example, sliders are good at pulling more pliable materials through mesh openings. Sliders are also often used with fibrous materials because they provide the shearing action needed to clear fibers from the screen’s openings. However, they are less effective when used with materials that tend to stick inside them. Since they can generate heat, consideration should be given to whether the material being processed is temperature-sensitive.

Hytrel polyester, nylon, and polypropylene sliders are all FDA-compliant. Regular polyester sliders are also available. Select from 7⁄8″ and 15/16″ thicknesses.