Technical Bulletins

Fiber Molded Products: 6 Ways To Minimize Scrap

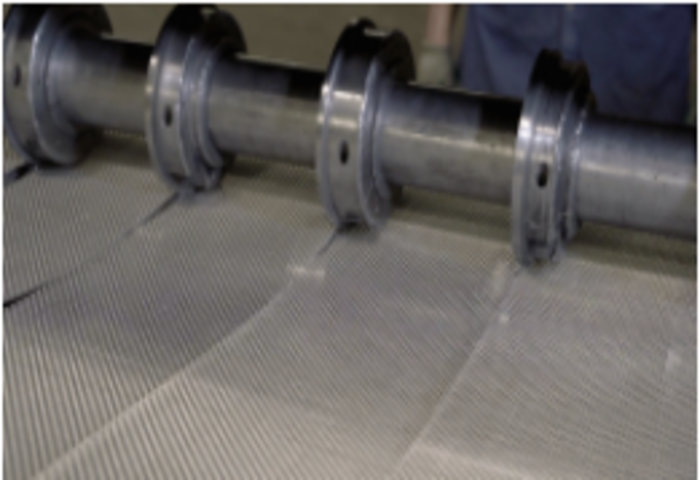

#1: Select Best Porous Media Type #2: Determine Correct Heat Treatment #3: Optimize Blank Layout Choosing the best porous media…

Fiber Molded Products: Minimizing Scrap and Lost Production Time when Drawing Wire Forms

In the metal fabrication industry, drawing has two meanings. One is the drawing of wire by taking it through a…

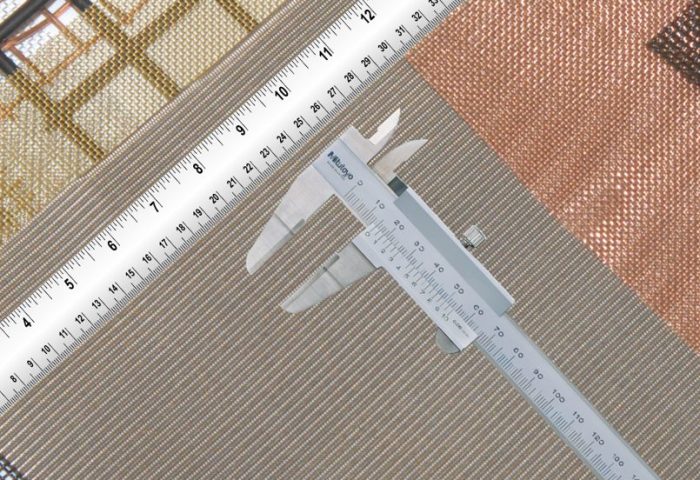

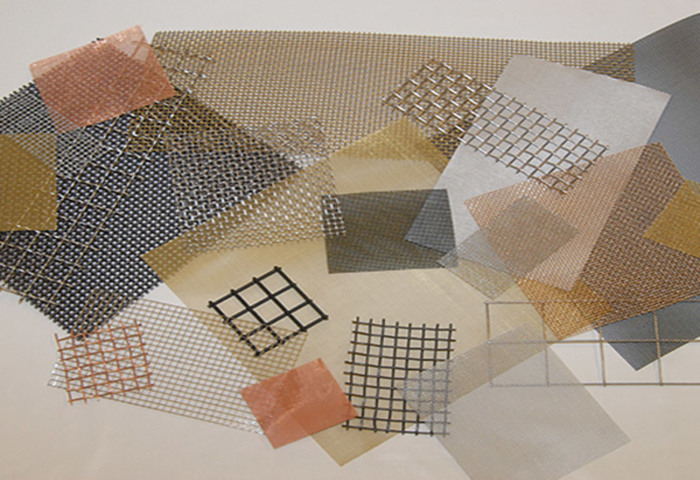

Beginners Guide to Wire Mesh: Understanding How to Specify Wire Mesh or Wire Cloth for your Application

Woven and welded wire mesh come in endless sizes and variations. In this article, we will discuss how wire mesh…

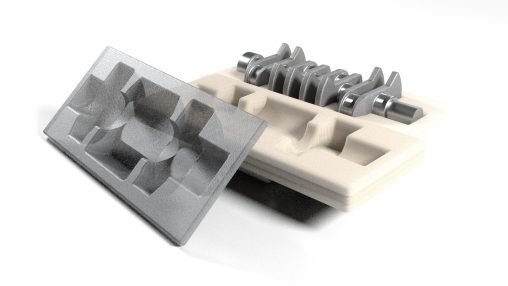

Fiber Molded Products: Shortening the Time to Market for New Products

Bringing any product to market is a lengthy and expensive process. In this article we will consider best practices for…

Fiber Molded Products: Why Choosing the Correct Porous Media Is Essential to Efficient Production

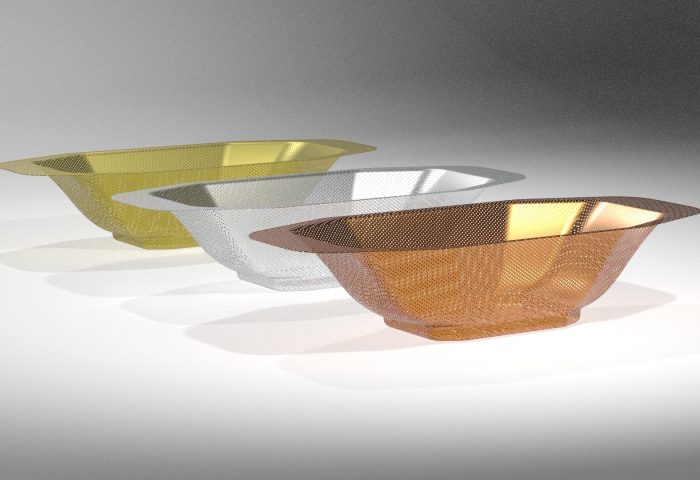

Molded fiber production began over 100 years ago as a protective and efficient way to package more delicate goods such…

The Secrets Behind Slitting and Shearing

Cutting wire mesh or cloth to a correct specification can be challenging. Wire mesh does not behave like sheet metal…

A Beginner’s Guide to Wire Mesh: The Basic Terminology

Each industry has its own specific terminology – and the wire cloth industry is no different. Below are the most…

A Beginner’s Guide to Wire Mesh: How to Choose the Correct Metal (or Alloy) for Wire Mesh Applications

Wire mesh, also known as wire cloth, is most commonly woven from stainless steel, however, with the right equipment and…

- « Previous

- 1

- 2