Hook Screens for Vibratory Machines

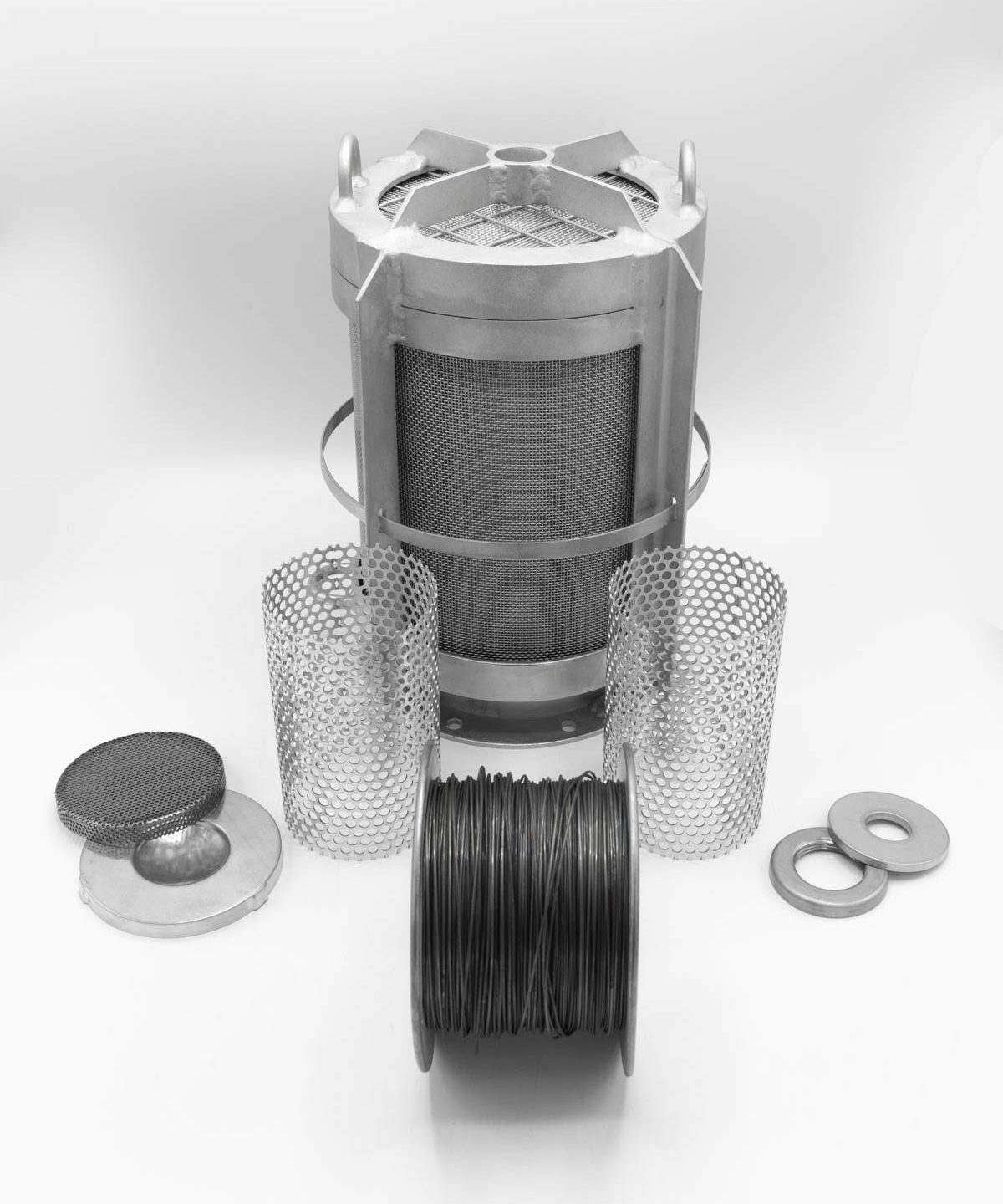

Hooked screens are vital to the sizing and grading required by many minerals, sand, and agricultural processes. Gerard Daniel hooked screens fit separators from leading equipment manufacturers. Quality fabrication ensures maximum shaker screen tension for extended service and optimum production.

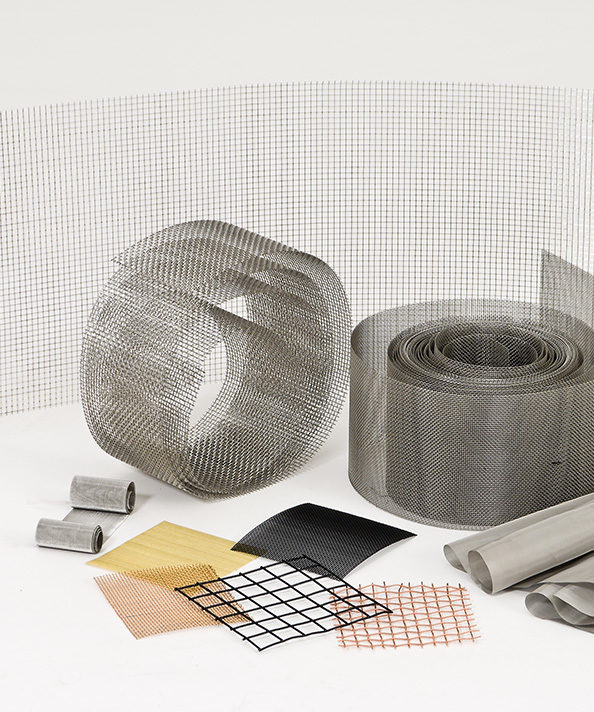

Mesh sizes range from large one-inch openings to 500 mesh. We supply screens with Type 2, Type 3, Type 5 hooks. We also supply Type 5 hooks with canvas inserts that protect the fine mesh from premature wear and tear, and we supply replacements for machine manufacturers. Our hook screens come standard with galvanized hooks. Specify stainless steel hooks when required by your application.

Gerard Daniel hooked sizing screens are vital to the sizing and grading required by many minerals, sand, and agricultural processes. Gerard Daniel provides vibratory screen mesh replacements for leading equipment manufacturers in these categories :

- Gravel screen mesh

- Mining screen mesh

- Quarry screen mesh

Quality fabrication ensures maximum shaker mesh screen tensile for extended service and optimum production.

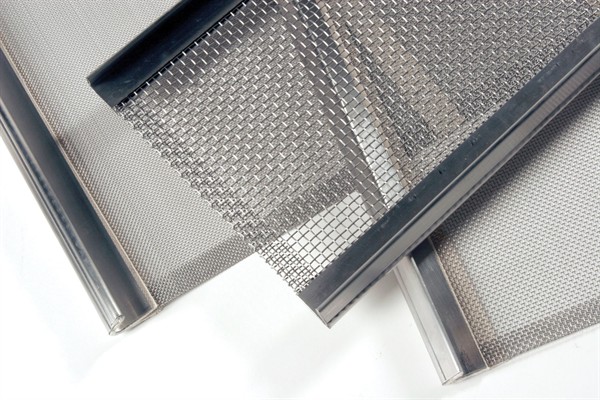

Mesh sizes range from large one-inch openings to 500 mesh. We supply shaker screen mesh with Type 2, Type 3, Type 5, Derrick, Reverse Mounted Mid-Western, and other specialty hook profiles, for sloped screeners, scalpers, and trommel screeners. We also supply hook profiles with canvas inserts that protect the fine mesh from premature wear from metal to mesh contact, and we supply replacements for machine manufacturers like Sweco® and Rotex®*. These banded hook screens come standard with galvanized hooks. Specify stainless steel hooks when required by your application.

Gerard Daniel supplies hooked screens in 12″ to 80″ screen widths. Select from multiple options:

- Single mesh layer

- Double-layer using a coarser mesh for top screen support

- Triple-layer screen – for specialized applications, upon request

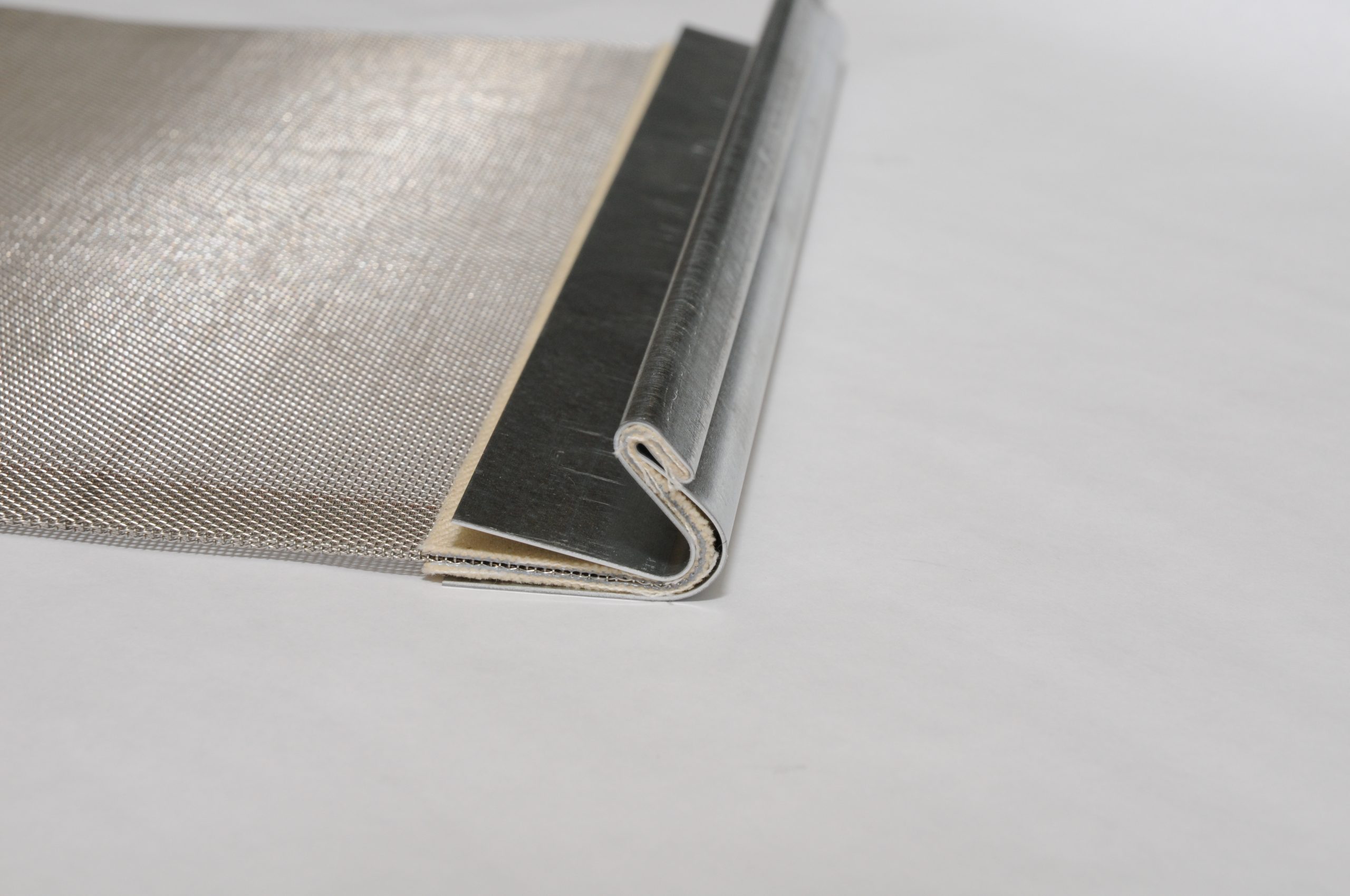

To prevent unraveling, open mesh edges are hemmed and bonded with plastic or canvas per manufacturer specifications or gasket to seal the open ends of the hook screen. High-temperature canvas is appropriate when process temperatures exceed 250 °F. The type of edge preparation must be compatible with the type of equipment and the characteristics of the material being screened. Quality edge finishing protects the operator when installing and the screen during handling.

Several style screens will require a partial canvas or full grid pattern that mirrors the supporting ball deck, to eliminate mesh to metal contact, eliminating premature failure, some style hook screens “Tyler Hummer” will have a canvas strip through the middle with a hole pattern matching the machine requirements for mounting purposes.

*Registered trademarks of Sweco® and Rotex®.