Pressure Leaf Filters

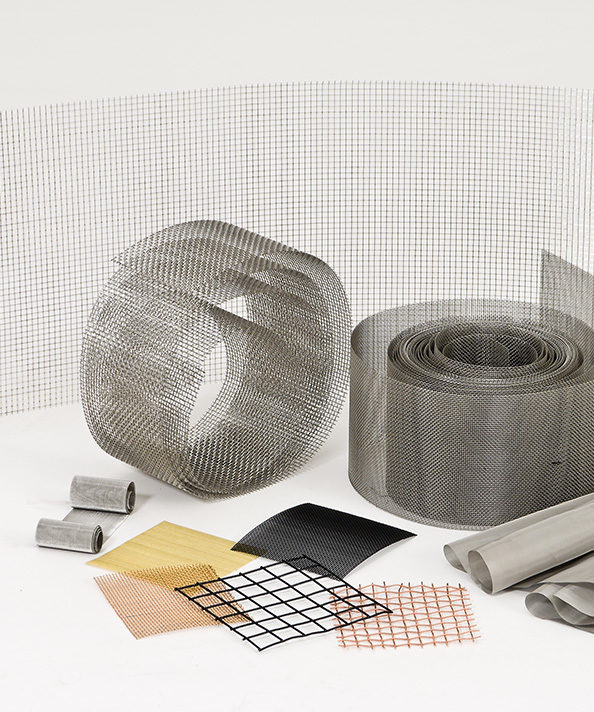

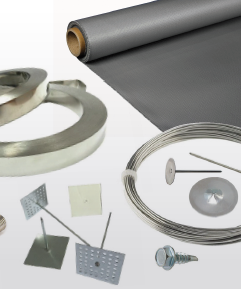

As a leading pressure filter leaf manufacturer, we work providing filter leaves for first installations and replacement designs. We can provide filter cloth and wire mesh made from a wide range of alloys. Our engineers are available to collaborate on filtration projects and provide both center and bottom discharge filter leaves to meet specifications.

Description

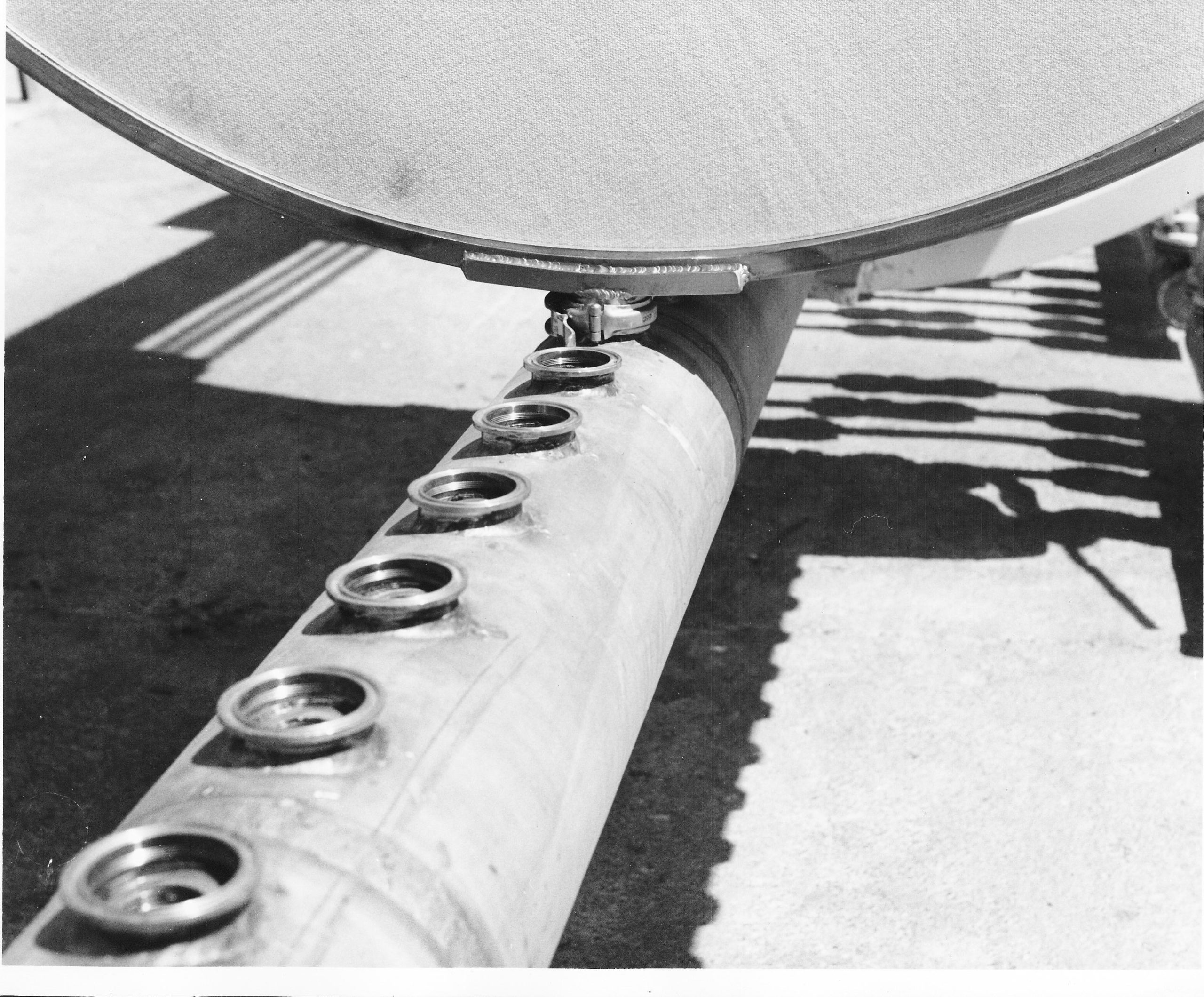

Pressure leaf filtration systems are used to separate liquids from solids. Filter leaves are the functional components of the pressure leaf filter vessel and depending on the vessel type, leaves may be either horizontally or vertically stacked in the vessel. The leaves provide filtering on both sides, which enables a large filtration area. Replacing old or damaged leaves with new or reconditioned leaves can bring immediate improvement to a filtration system’s performance.

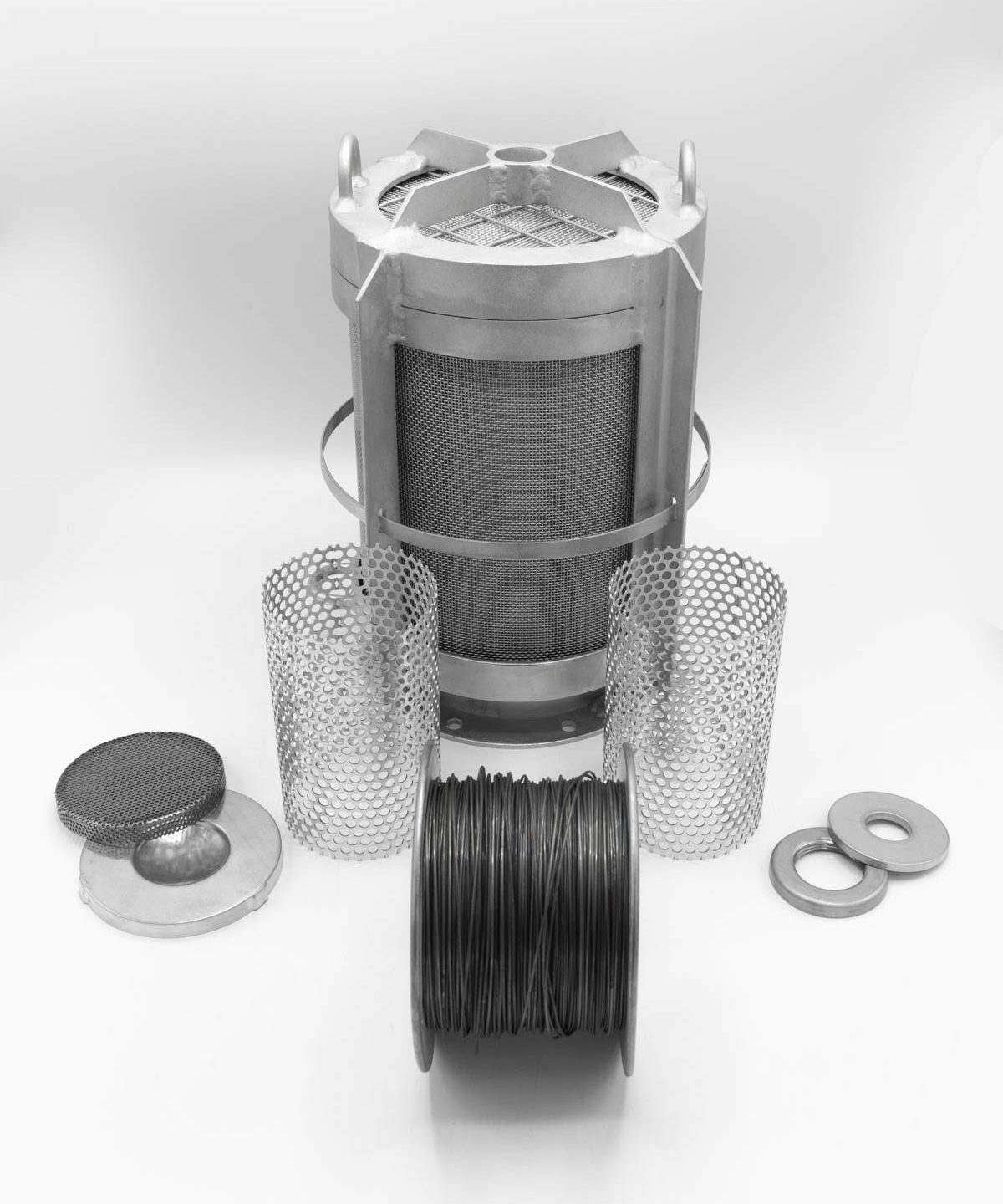

Construction

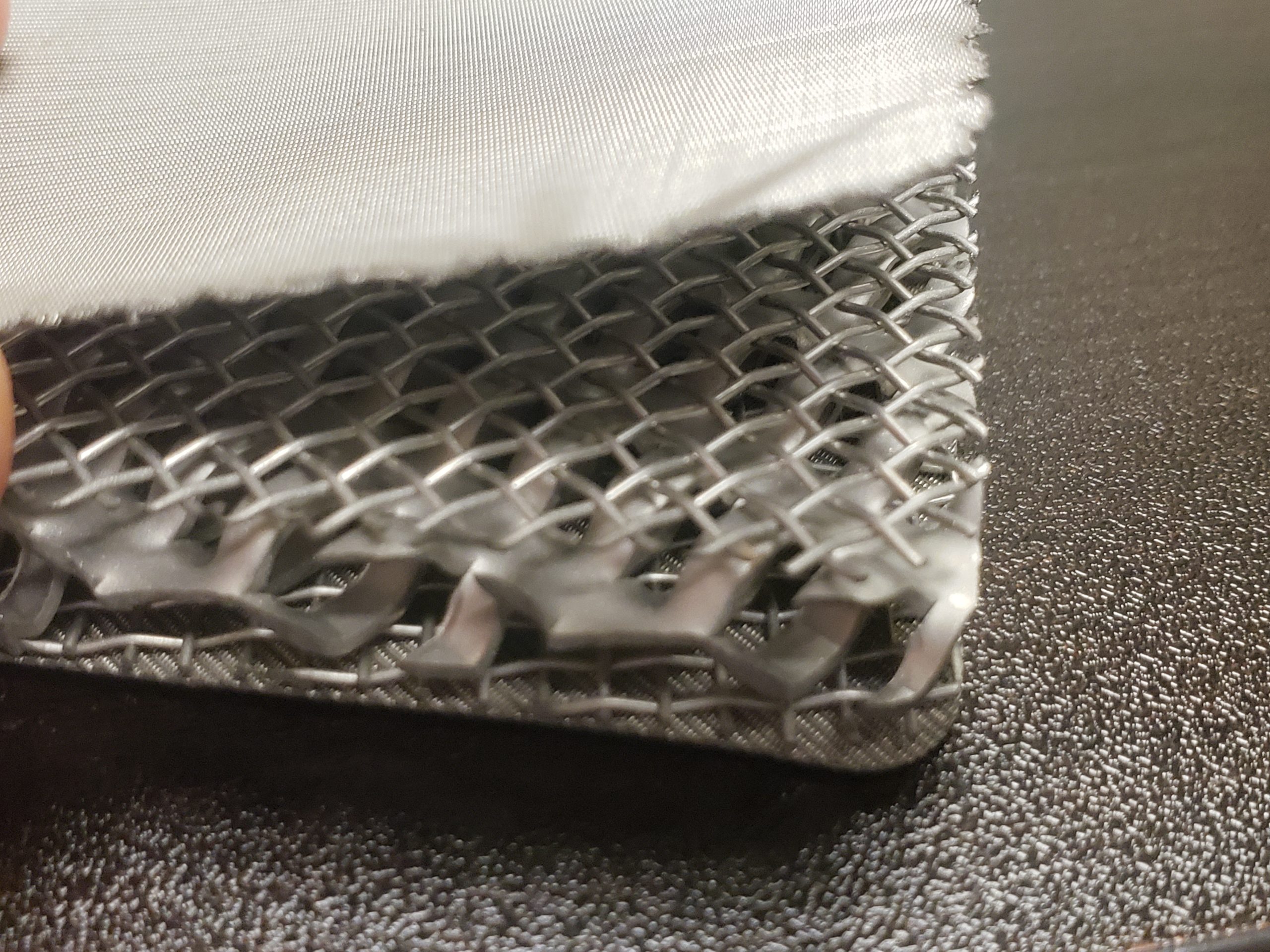

- Stainless Steel – 304L, 316L, 904L, Alloy 20

- Duplex Titanium, Monel Alloy 400, or other specialty alloys are available on request.

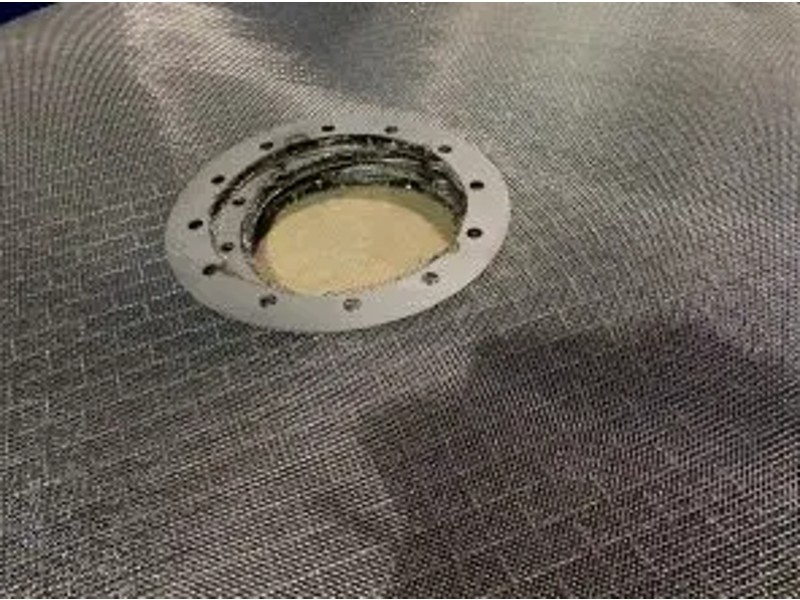

- Riveted or welded to hub and rim

- 3 ply, 5 ply, 7 ply or built to spec.

- Rectangular, Circular, Custom shapes

- Filter Leaf Micron Sizes

- Standard: 60-110 µm

- Custom Mesh sizes woven to spec

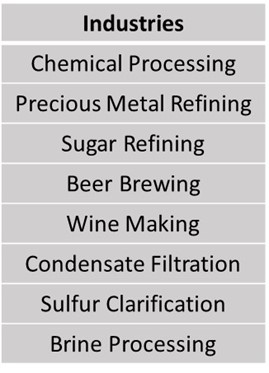

Applications and Industries

Filter Leaf Replacement:

Customers in many industries will often approach Gerard Daniel for help replacing filters when their performance begins to degrade, or parts become damaged. Sometimes they know what the specs are, but many times they do not. Our engineers will work with them to replace their filters with new ones designed and manufactured to meet or even improve performance over the original specification. We can also re-design our customers’ existing filters to deliver a stronger, more durable leaf.

Custom Filter Leaf Development:

We can also work with manufacturers directly, developing filter leaves to provide the most effective solution for their designs. Our Engineers use their many years of experience to specify a mesh weave and production method that will maximize the flow within the vessel with less pressure differential. Once the design is proven and qualified, we produce filter leaves to that exact specification, delivering when required, directly to our customers’ production lines.