Acoustic Mesh

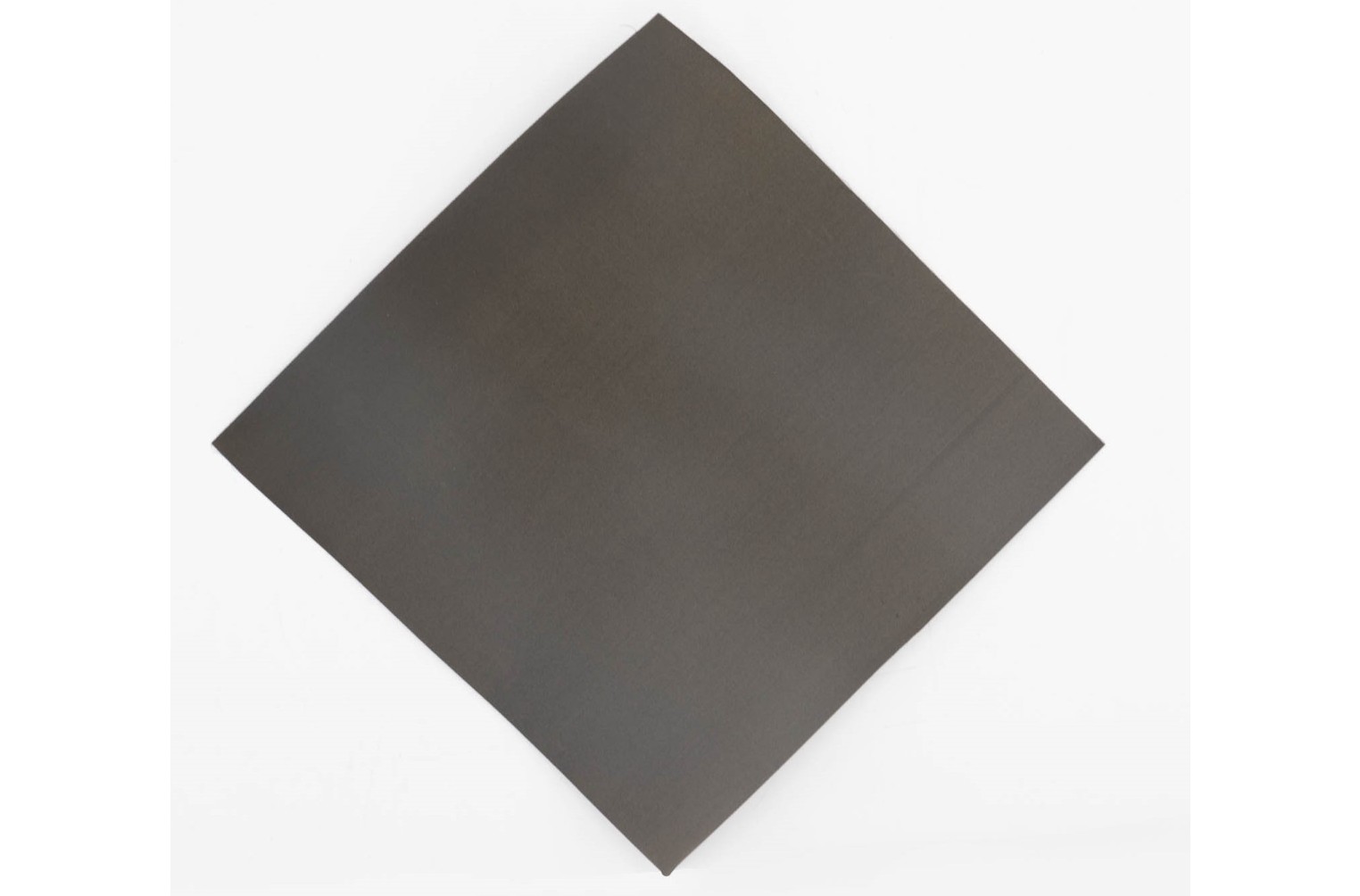

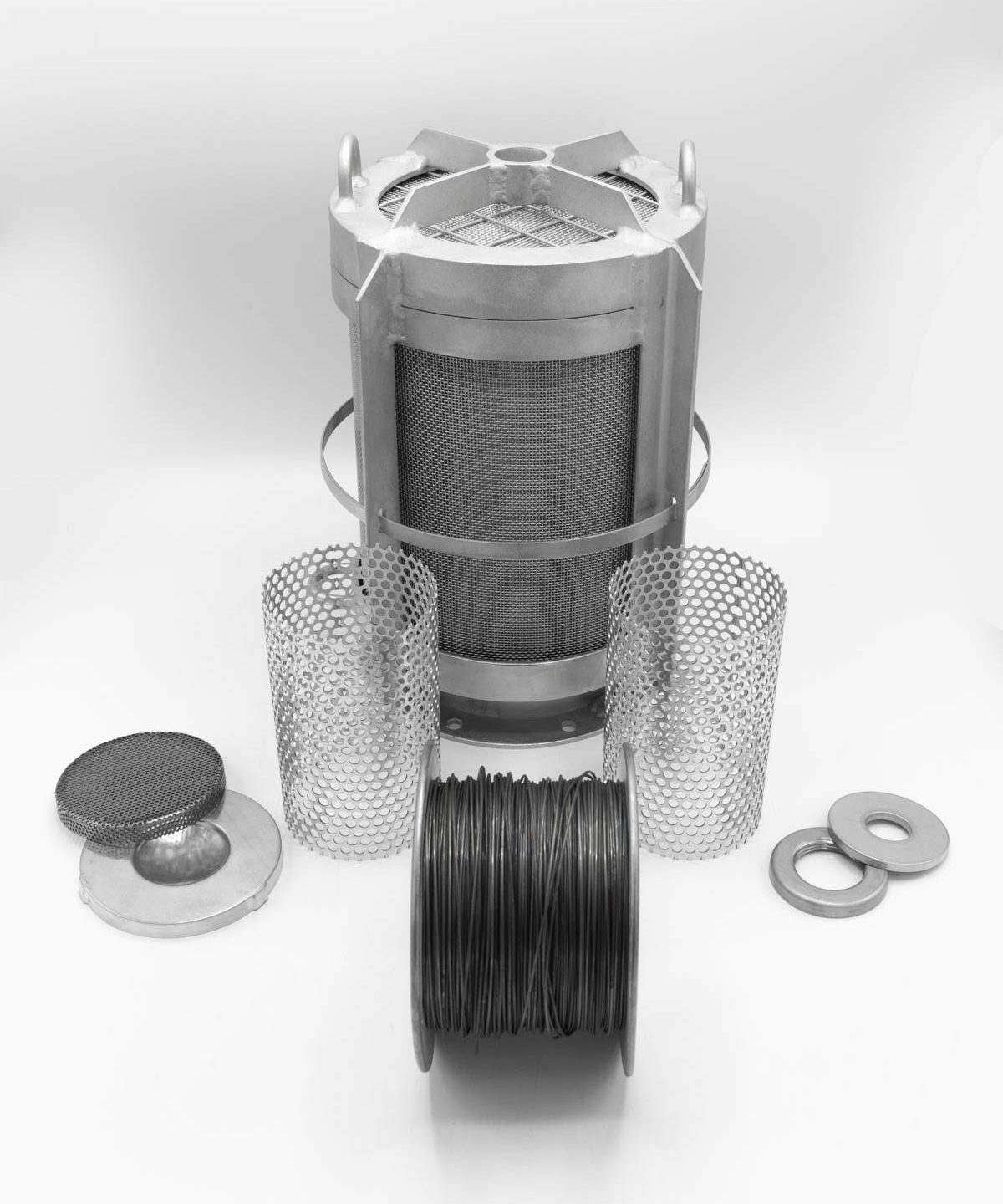

Acoustic mesh is a particular type of wire mesh used to achieve precise sound attenuation or noise suppression objectives used in aerospace (typically nacelles and thrust reversers in jet engines) and consumer electronic noise reduction applications. It is woven to a precise Rayl value, which is a measure of acoustic impedance or airflow resistance.

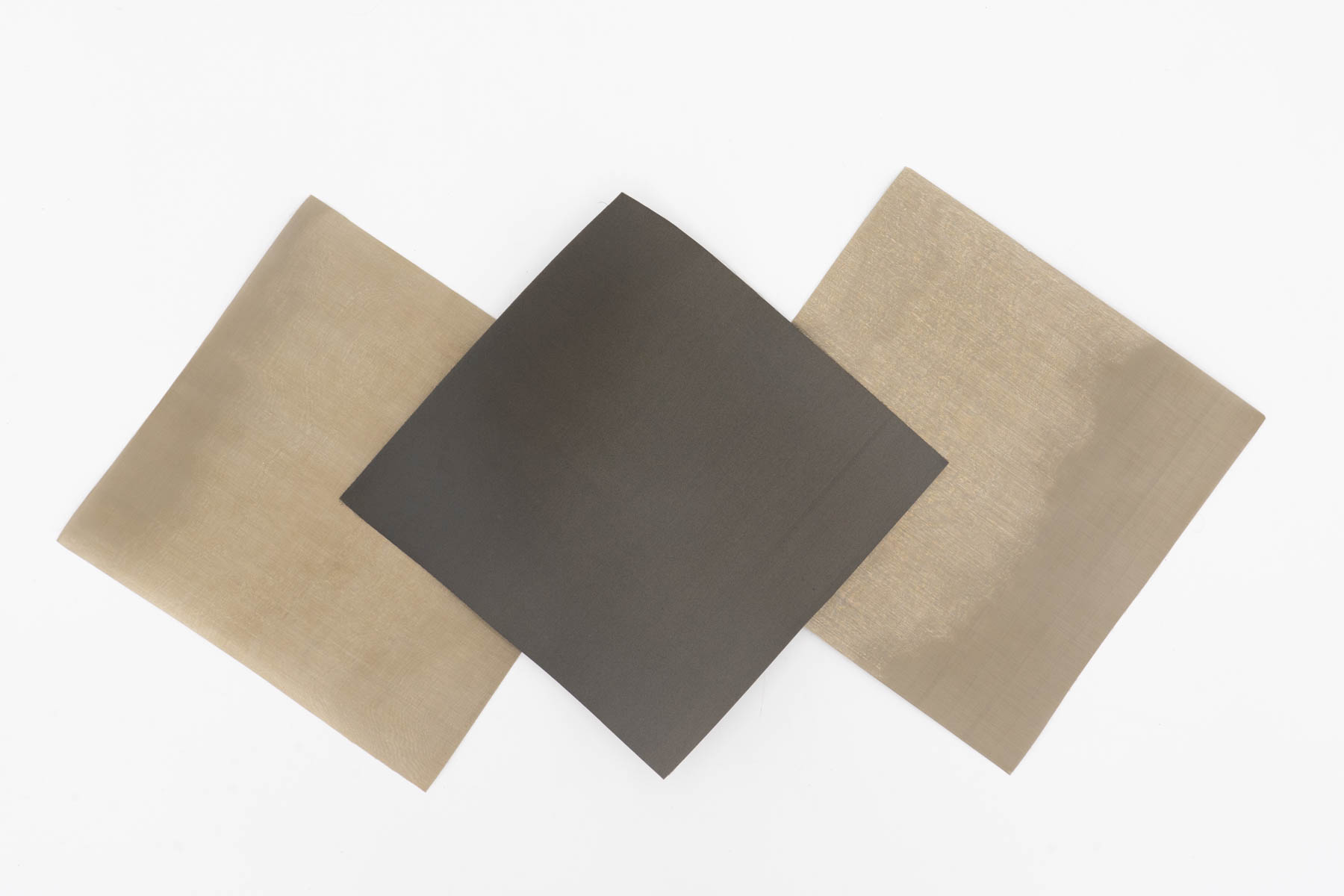

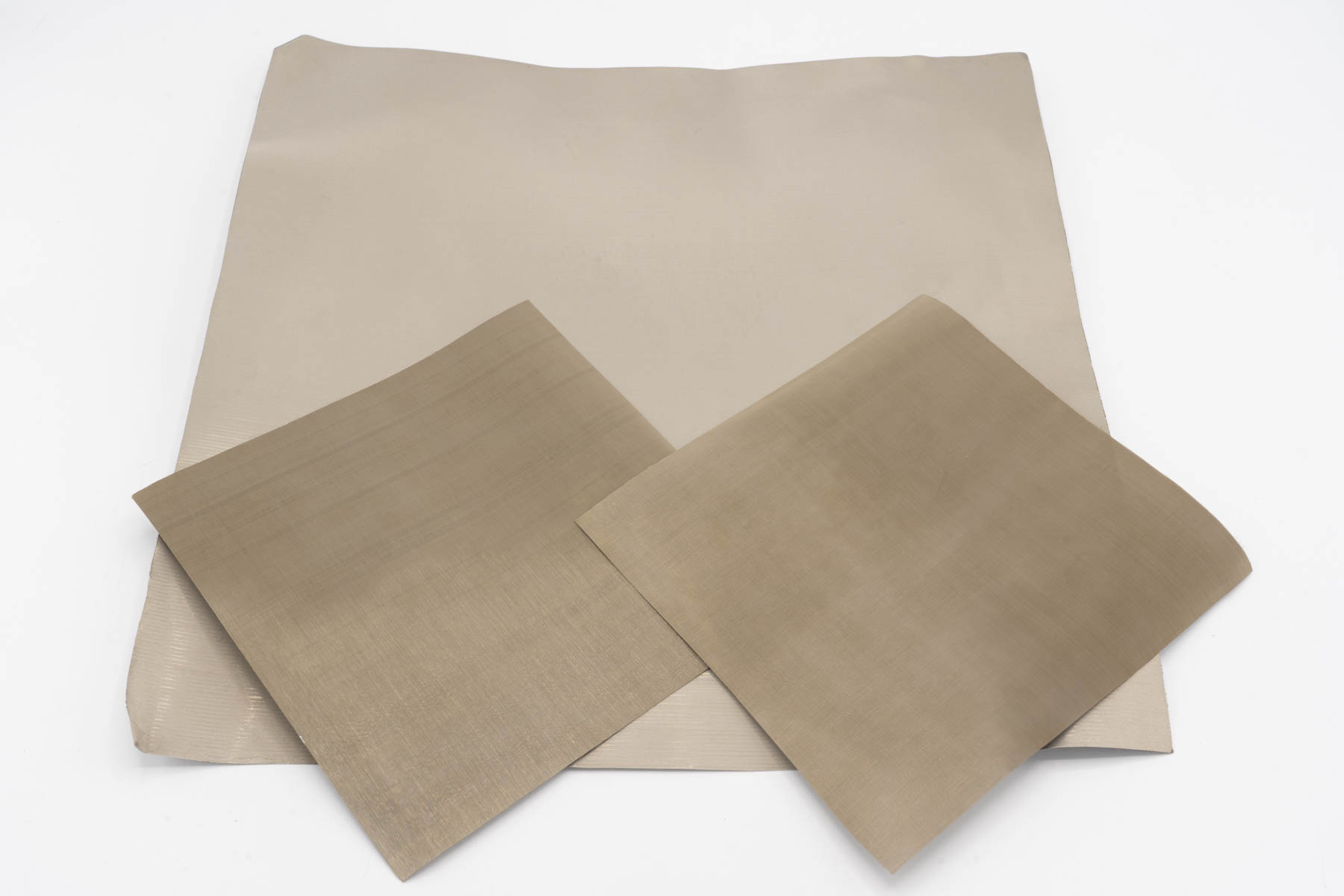

Acoustic mesh can be woven from a wide range of mesh types, from plain square metal mesh with a greater open % area, to complex Dutch, Reverse Dutch, and Twilled weave patterns designed to produce a much finer open area and sound attenuation qualities. The latter is far more common in most acoustic applications.

Our experienced weavers bring many years of experience and knowledge in weaving acoustic mesh. What sets us apart is our efficiency and accuracy – for example, we continually measure the Rayl value of the mesh as it’s being woven and can make minute tweaks to ensure that it stays in specification even before it’s officially certified to the Rayl value in our quality lab.

We have the capability to weave acoustic mesh to meet Rayl values in the following ranges:

- 3 – 100+ on the CGS scale

- 30 – 1000+ on the MKS scale

We can also weave to a custom Rayl value. Often a customer will send us a sample with an unknown Rayl value and ask us to match the performance. Our skilled weavers and engineers will work with them to match it or advise the most suitable mesh depending on the application.

Material Specifications for Aircraft Acoustic Mesh

Gerard Daniel manufactures acoustic mesh to specific Rayl values to support aircraft engine manufacturers and aftermarket services providers meet their material specifications for nacelles and thrust reversers. Following are the specifications that Gerard Daniel meets and routinely delivers to their customers:

| SMS 54 Issue 4 | SMS 65 Issue 1 |

| NRM 1-2 Revision F | NTR-MS-0402 Revision NC |

| RMS-059 Revision K | MDL 8050 Revision 2 |

| HMDM0011B Revision B | HMRM0003 Revision B |

| 10 Rayl | PWA 1170 Revision P |

| CPW 656 | AMS 5690 Revision M |

| PWA 83 Revision AD | STM-P-H109 |

| VM 1014 | VSS7022 Revision A |

| Part marking & identification RPS 13.99 Revision AA | Cleanliness requirements for the controlled contamination area (CCA) RPS 17.34 Revision H |

Since Gerard Daniel manufactures acoustic mesh to each customer’s exact requirements, we stock only those products our customers have on our Customer Replenishment System. However, we can produce prototype examples either to match an existing Rayl value or to test in a new product application.

Contact us to request a quote or to provide samples or prototypes for your next project.

Frequently Asked Questions

Find answers to common questions about acoustic mesh.

What is acoustic mesh?

Acoustic mesh is a precisely woven wire mesh designed to control sound attenuation and airflow resistance. It’s engineered to achieve a defined Rayl value, a measure of acoustic impedance that determines how sound waves pass through or are absorbed by the material. Gerard Daniel manufactures acoustic mesh for aerospace applications, such as nacelles and thrust reversers, as well as for consumer electronics where noise suppression is critical.

How is acoustic mesh used in aerospace applications?

In aerospace, acoustic mesh is integrated into jet engine nacelles, thrust reversers, and exhaust liners to reduce engine noise while maintaining airflow. Gerard Daniel’s meshes are woven to strict Rayl and OEM specifications to meet the performance and regulatory standards of major aircraft manufacturers and aftermarket service providers.

What does the Rayl value mean in acoustic mesh?

The Rayl value measures the airflow resistance or acoustic impedance of a mesh. A higher Rayl value indicates greater resistance and more sound absorption, while a lower value allows more airflow. Gerard Daniel weaves mesh to Rayl values ranging from 3–100+ on the CGS scale and 30–1000+ on the MKS scale, or to any custom Rayl value specified by the customer.

What weave patterns are used for acoustic mesh?

Acoustic mesh can be woven in a variety of patterns depending on the desired porosity and sound attenuation characteristics. These include plain square weave, Dutch weave, reverse Dutch weave, and twilled weave designs. The finer Dutch and twilled weaves are typically used for high-performance acoustic control.

What materials are used to manufacture acoustic mesh?

We typically use stainless steel, Inconel®, Monel®, and Nickel-based alloys that can withstand extreme temperatures, vibration, and corrosion common in aerospace environments. Material choice depends on acoustic requirements, durability, and compliance with specific OEM material standards.

How does Gerard Daniel ensure precise Rayl values during production?

Our weavers continuously monitor and measure Rayl values in real time during the weaving process. This allows for minute adjustments before the mesh is certified in our quality lab, ensuring every batch meets exact acoustic specifications and OEM standards.

Can Gerard Daniel match an existing acoustic mesh sample?

Yes. Many customers send us samples with unknown Rayl values. Our team measures the acoustic impedance, identifies the weave and material, and either matches the performance or recommends an optimized mesh design for the target application.

What industry specifications does your acoustic mesh meet?

Gerard Daniel routinely manufactures mesh to meet aerospace specifications, such as:

SMS 54 Issue 4, NRM 1-2 Revision F, PWA 1170 Revision P, AMS 5690 Revision M, and RPS 17.34 Revision H, among others. We maintain full documentation for traceability, cleanliness, and part marking per customer and regulatory requirements.

Do you stock standard acoustic mesh, or is it custom-made?

Because every acoustic mesh is woven to customer-specific Rayl values and specifications, we only stock items under our Customer Replenishment System. However, we can quickly prototype new meshes to match existing parts or evaluate performance in new designs.

How can I request a quote or prototype sample?

Simply contact our engineering team with your target Rayl value, application details, or a physical sample. We’ll collaborate to confirm your acoustic performance requirements and deliver prototype meshes or production runs tailored to your specifications.

Frequently Asked Questions

Find answers to common questions about square/plain weave wire mesh.