Performance™ Series Vibratory Separators Overview

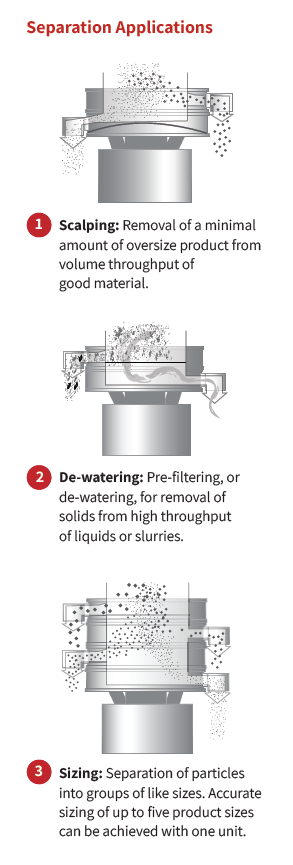

Our Performance Series of round vibratory separator machines effectively sieve dry goods by size or separate liquids from solids. Proudly made in the USA, engineered to last, and built with high quality components, our separators are well suited for liquid-solid separation, wet or dry classification, and dry separation.

For details of our product line, watch our videos.

Performance Series Vibratory Separators

(Click the machine or series name for details)

| Machine Range | Compact™ | Performa™ 24 | Performa™ 30 | PerforMAX™ 48 | PerforMAX™ 60 |

|---|---|---|---|---|---|

| Nominal Screen Diameter | 18 in (457 mm) | 24 in (610 mm) | 30 in (762 mm) | 48 in (1219 mm) | 60 in (1524 mm) |

| Screen Area | 254 in2 (1635 cm2) | 450 in2 (2900 cm2) | 700 in2 (4500 cm2) | 1800 in2 (11,600 cm2) | 2800 in2 (18,000 cm2) |

| Utilization | Lab Analysis, Occasional Use, Small Batch Sizes, Startups | Medium Throughput | Medium Throughput | High Production | High Production |

Machine Selection

- Our Performance Series vibratory screeners-separators are all equally capable to screen, sort, sieve, classify, or dewater any material you put in them.

- Choosing the right size separator depends on the throughput required, the physical space available to you, and the power supply to your operation – read how or use our app below.

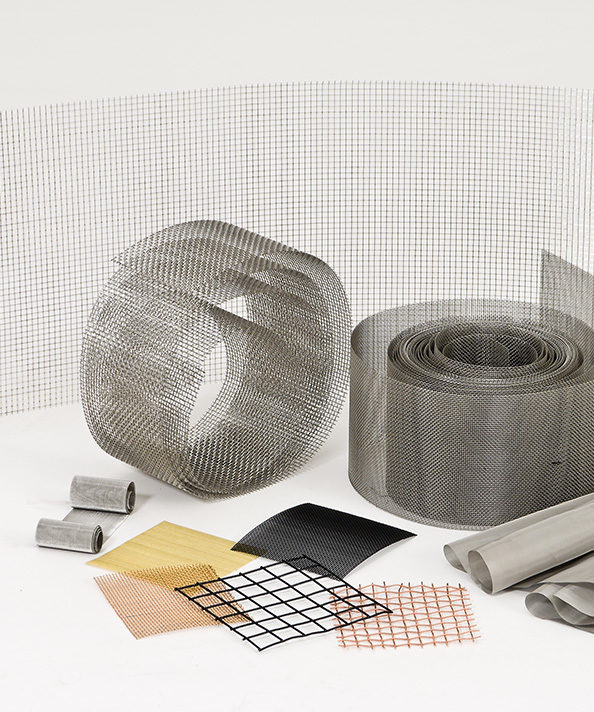

Screen Selection

Screens can be selected for sifting, sieving, and screening any material. Questions? Talk with our experienced Engineers about your application.

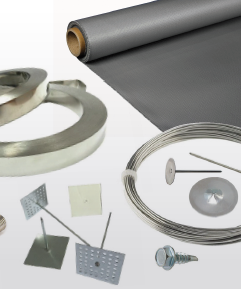

Deblinding Your Screens

- How to choose the right de-blinding solution.

- Find the correct part

Typical Applications

- Food & Beverage

- Nutraceuticals

- Herbs and Spices

- Plastics

- Abrasives

- Ceramics

- Pharmaceuticals

- Mining

- Cannabis

- Commercial Laundries

Why Gerard Daniel

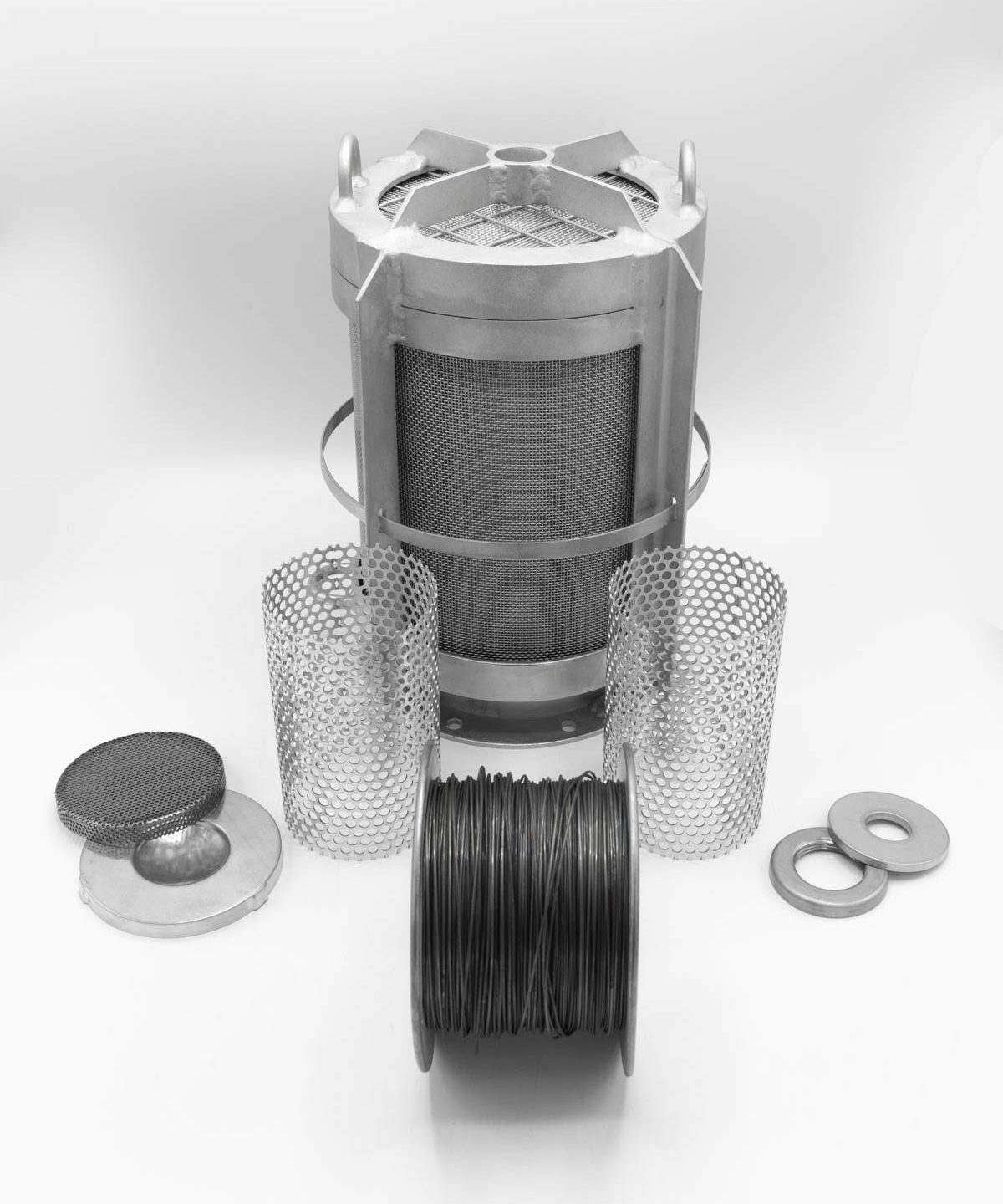

Various types of vibratory separators have been in use for decades. However, while many parts of major separator machine brands are interchangeable, we use our deep expertise in woven mesh to recommend a screen gradation to suit the customer’s need precisely, rather than using a “cookie-cutter” approach from standard mesh, resulting in maximum production rates. We build every Performance machine in our US plant using the best quality materials and continuous welding, to provide a durable sanitary separator machine intended to last for decades.

We also differentiate ourselves by delivering personal customer service. We help our customers make good decisions about the right machine for their applications and ship their units fast. With over 70 years of experience in wire mesh solutions, our applications engineers have the know-how to pair you with the right size machines, the right screens, and the right accessories; to get you up and running as quickly as possible. We also provide responsive aftermarket support to keep our customers’ equipment in good operating condition.

A circular vibrating screen allows small particles (or liquid when used as a solid liquid separator) to fall through the screen, while particles too large to pass through are conveyed off the edge in a spiral by the gyration of the screen. By carefully selecting the mesh and stacking up to four screens of increasing mesh opening size, users can separate or classify material into multiple sizes

Separator Parts Available for Most Manufacturers: Sweco, Kason, and More

We can replace or repair parts for virtually any other OEM sifter – sieve machine manufacturer, including a Sweco vibratory screener, Midwestern, Kason, Russell Finex, etc.

Our machines are CE and FDA certified and compliant to the specifications of the following bodies – CFIA, USDA, 3A Sanitary Dairy, ASTM, HPRA.